CASE STUDY

Ballast Tank Refurbishment – Crude Oil Tanker

Client: AET Ship Management

Industry: Marine

Scope: Ballast Tank Refurbishment

Date: September 2014

Location: China

Products: RS 500P

OVERVIEW

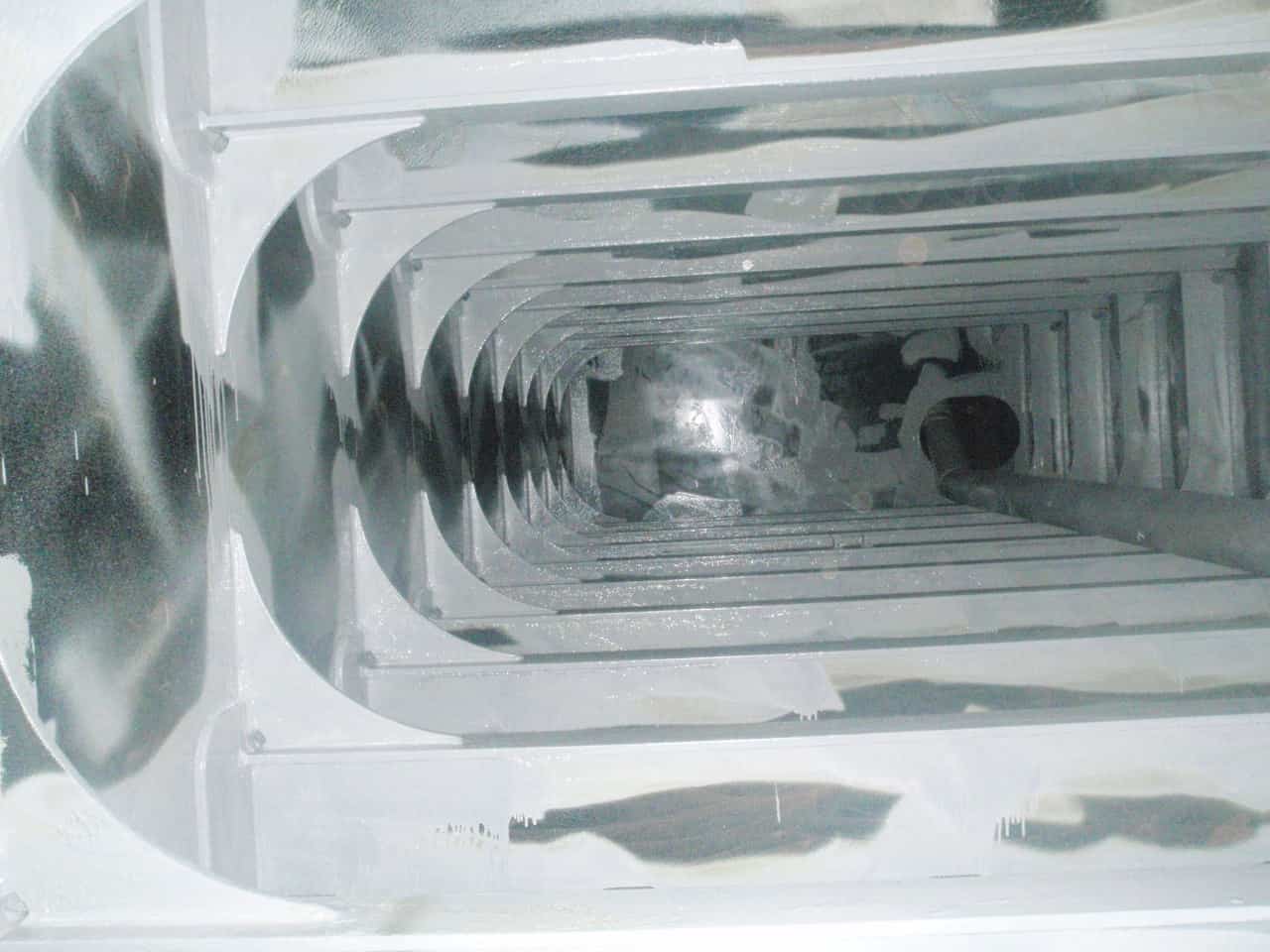

The sea water ballast tanks on board the Crude Oil Tanker required a refurbishment (over 36,000m²) after the original coating was showing severe signs of corrosion damage.

CHALLENGE

To treat and protect the corroded areas located in the ballast tanks without damaging the intact painted areas. There was also a limited time frame to complete this project.

SOLUTION

High pressure water jetting (1,000 bar) was utilised as the surface preparation method with inaccessible areas prepared by mechanical preparation. One stripe coat of solvent-free, wet & rust tolerant epoxy Epo-chem™ RS 500P was then applied. This was followed by one touch-up coat of Epo-chem™ RS 500P.

OUTCOME

The project was completed on time and to the complete satisfaction of all concerned.

BENEFITS

• Solvent-free

• No grit blasting

• No humidity or dew point restrictions

• No disruption to other ongoing work (including hot work)

• Reduced H&S and Fire Precaution

• Reduced contract duration

• Unlimited over-coating