CASE STUDY

Barrage Refurbishment

– NORSOK M-501 System 7a

OVERVIEW

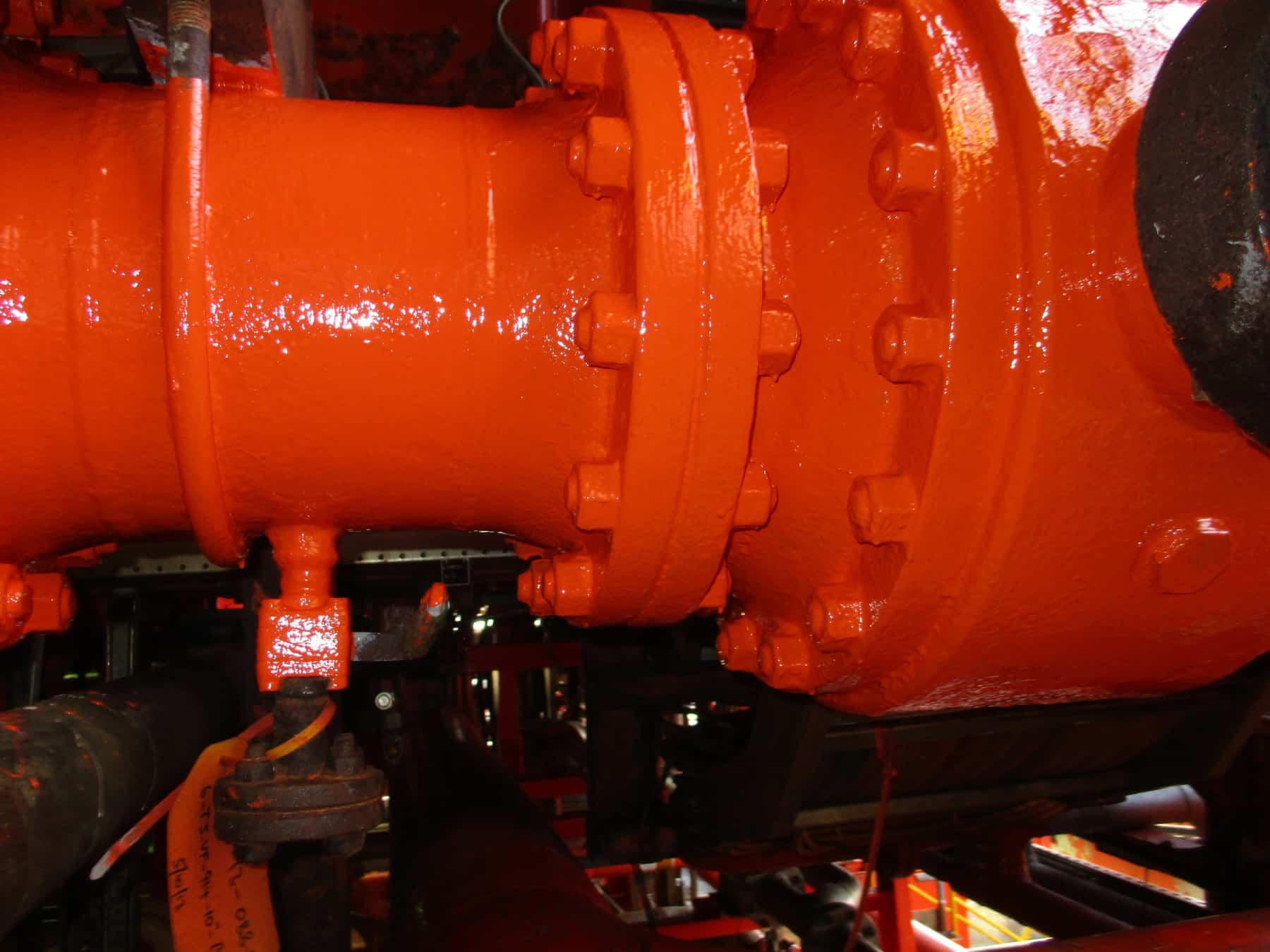

A large barrage, used to regulate the flow/supply of water between a national loch and power station, was selected for refurbishment with the view to being put back into long-term service.

The barrage was constructed by the Lead Fabrication Contractor for the project, AJT Engineering.

The coating works were undertaken by the Lead Coatings Contractor for the project,

PBP Services (Scotland) Ltd.

CHALLENGE

The structure of the barrage was made up of different sections, with each section having to be coated and returned to service within a relatively short timeframe.

The client was looking for a coating system to last 20+ years whilst ensuring the ability to provide corrosion protection, withstand a high level of water flow and abrasion from its moving parts, and retain its coloured finish.

SOLUTION

It was decided that a specification based on Chemco’s NORSOK M-501 System 7a was to be selected for the project, as follows:

- Primer Coat – RS 500P

- Intermediate Coat – RA 500M

- Topcoat – RC 500GTC

This coating system was applied, by stripe coat and full coat, on all areas of structural steel.

This included gates, beams and hinges.

OUTCOME

The project was completed within the given timeframe and prepared for a return to service.

The selected Chemco system was given with a life expectancy of 20+ years.

BENEFITS

- Solvent-free / VOC compliant

- Wet & rust tolerant

- Surface preparation flexibility

- No humidity or dew point restrictions

- No recoating limitations, meaning ease of repair

- Quick return-to-service

- Long term corrosion protection, chemical resistance and abrasion resistance

- Improved Health & Safety and reduced risk of Fire Hazard

- Excellent long-term colour stability and opacity

- Amine, NCO and isocyanate-free