CASE STUDY

Chemical Storage Tank Lining

OVERVIEW

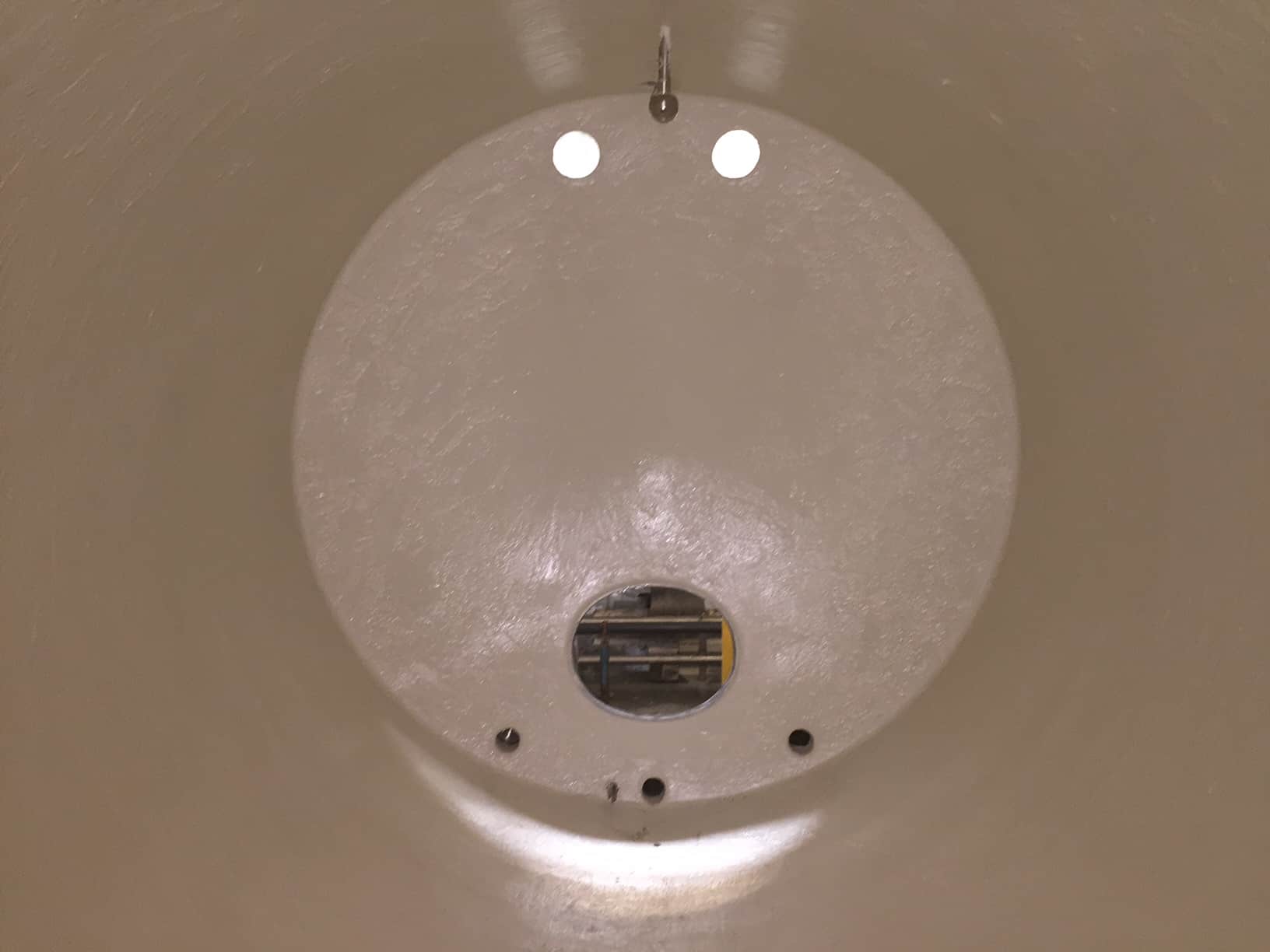

Stainless steel chemical storage tanks used to store various aggressive acids and alkalis were beginning to corrode and required to be completely refurbished.

CHALLENGE

The previous coating had to be completely removed and replaced with a new lining system which could provide protection from the full pH range. The new lining system also had to have exceptional adhesion to a stainless steel substrate.

SOLUTION

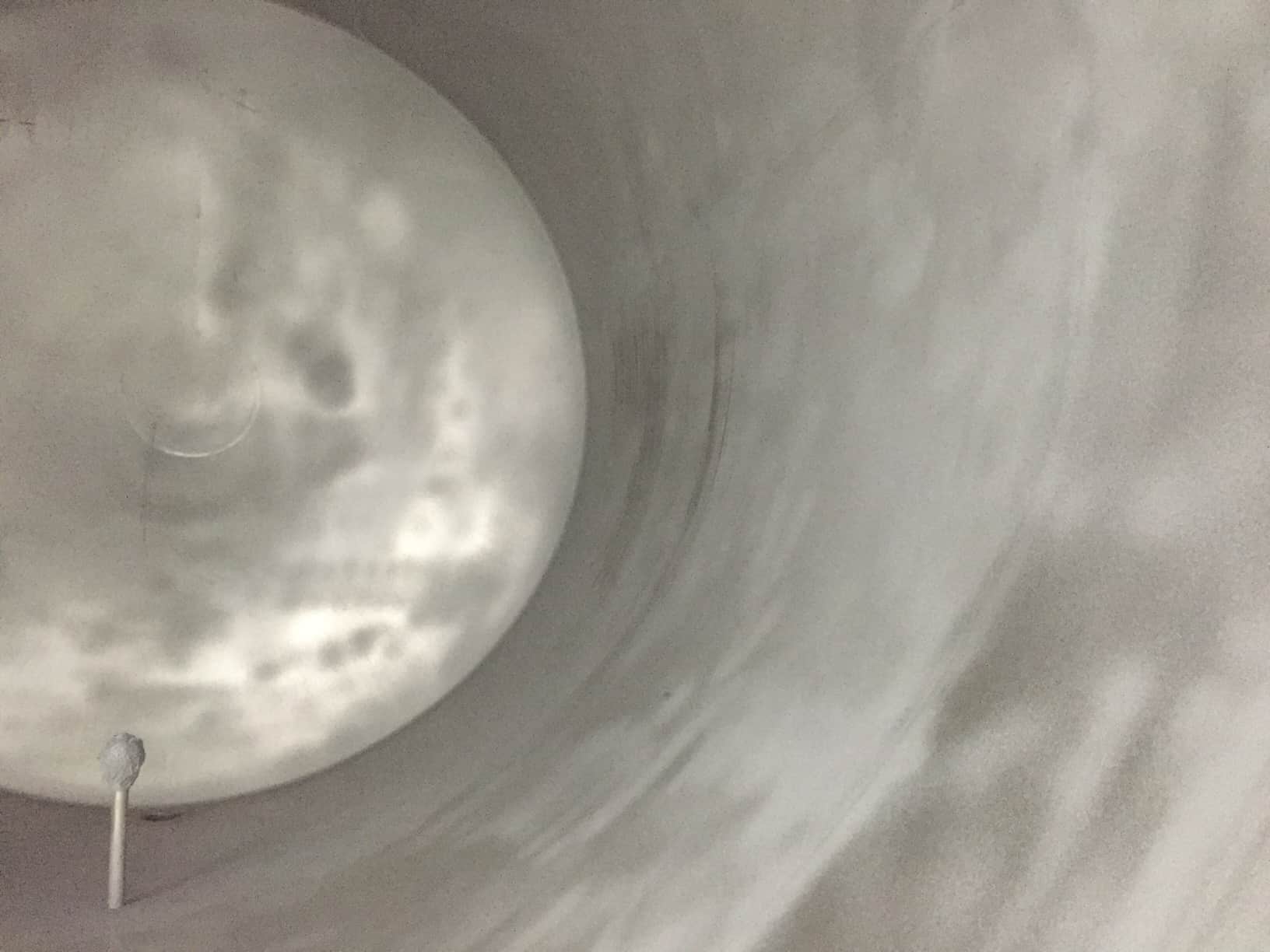

The tank internals were abrasive blasted to Sa 2½ standard, completely removing the previous coating and leaving a clean white metal for the new coating system. One coat of Chem-tect™ RC 300 was applied first to ensure a high level of adhesion to the stainless steel substrate. This was then over-coated with one coat of highly chemical and high temperature resistant Chem-tect™ RB 300.

OUTCOME

The work programme was successfully completed within the given time frame. The unique combination of these two Chemco coatings will ensure that long-term maintenance-free protection against the full pH range is provided.

BENEFITS

• Exceptional resistance to the full pH range (1-14)

• Excellent resistance to the most aggressive chemicals operating at high temperatures

• Outstanding adhesion to stainless steel substrates

• Fast curing