NEWS

Coal-Tar Epoxy Repair System

At Chemco, we have developed a protective coating system which can be utilised as a repair or patch repair system of coal-tar epoxies traditionally found in ballast tanks which has no compatibility issues.

Repair or patch repair work of coal-tar epoxies is an area in which many companies face great difficulty. For work of this nature, solvent-based paints cannot be used as the solvent in these products will attack the bitumen in the coal-tar epoxy and melt away the coating. Therefore, solvent-free products must be used to carry out this type of repair work.

The Chemco solution is a two coat system, comprised of the following coatings:

- One primer coat of solvent-free, wet & rust tolerant epoxy Epo-chem™ RS 500P

- One topcoat of solvent-free, wet tolerant, glassflake epoxy Epo-chem™ RA 500M

Depending on convenience and suitability to the client, any surface preparation method can be undertaken (water jetting, mechanical preparation or grit blasting). The two coat system could then be applied as soon as the surface preparation was complete; due to the wet & rust tolerant properties of this solvent-free system.

For repair work, the flexibility of surface preparation method brings with it the additional benefits that grit blasting does not need to be utilised. Eliminating this expensive and time consuming method would save the client substantial time and cost.

The environmentally friendly surface preparation method used in conjunction with the solvent-free (odourless) coating system significantly reduces Health & Safety standards and Fire Precautions. This system also allows other nearby ongoing work (including hot work) to continue nearby with no disruption (no operational shutdown required).

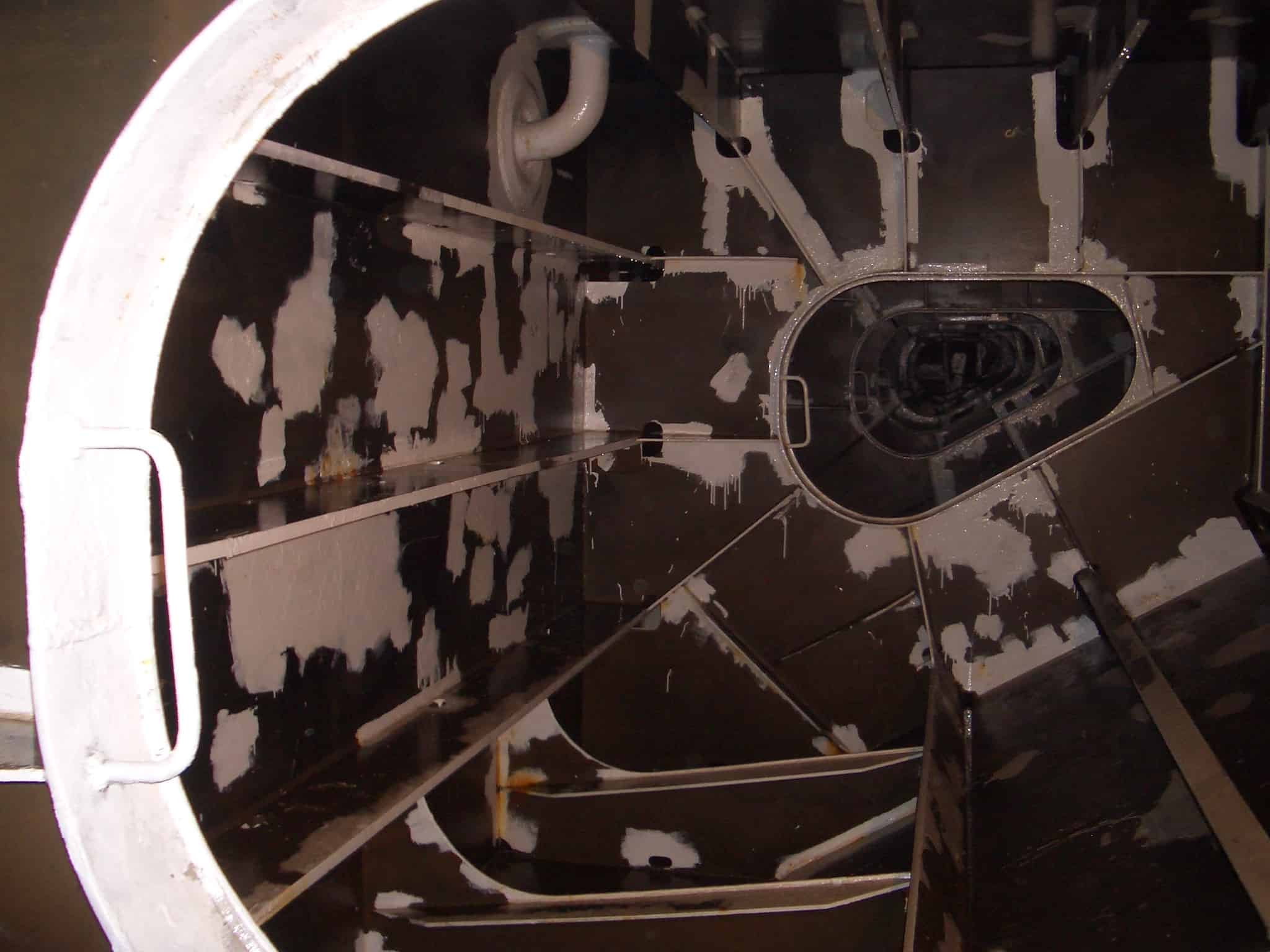

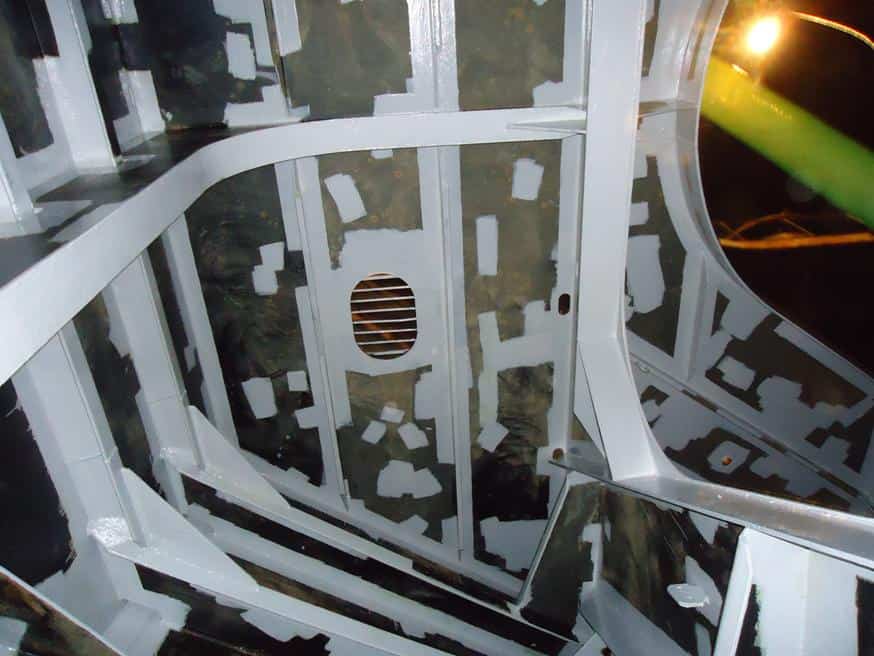

Completed Application

Completed Application

Related Products…

Contact Our Specialist Coating Advisors…

Our coating specialists can suggest the right solution for your specific application.