CASE STUDY

Cruise Ship Alkali Tank Refurbishment

OVERVIEW

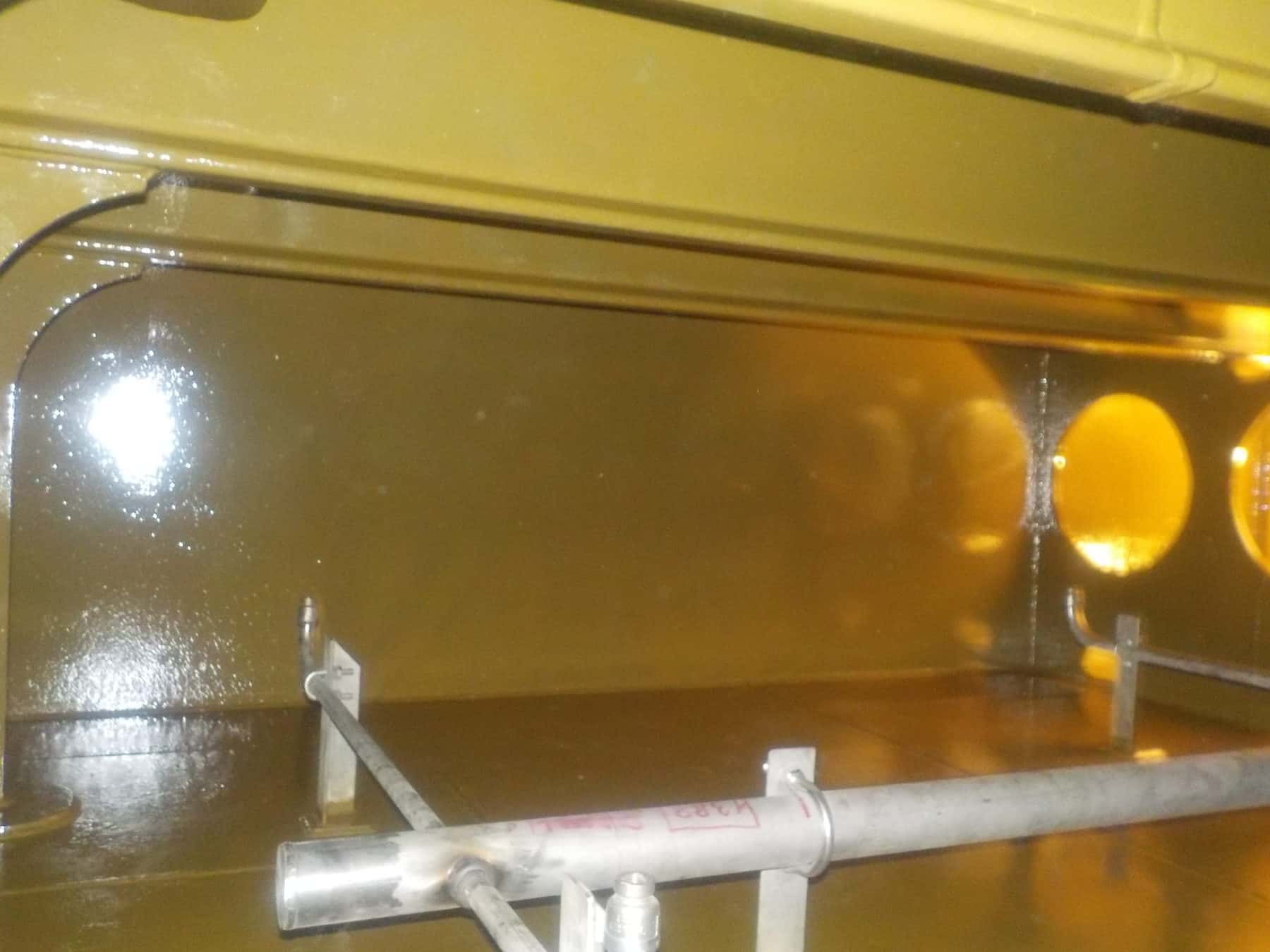

The alkali tanks on board a large cruise ship were suffering from corrosion due to breakdown in the previous paint system.

Chemco was tasked with providing a new coating solution for the refurbishment project.

CHALLENGE

The internal conditions in each tank had to be measured accurately in order for the correct coating system to be specified.

It was established that the chosen coating solution had to withstand a relatively strong alkaline environment with temperature exposure of greater than 60°C.

SOLUTION

Chemco was able to provide a solvent-free, rust tolerant, high temperature glassflake epoxy Novolac coating system:

First Coat: RE 500P 100μm

Second Coat: RW 500 250μm

Third Coat: RW 500 250μm

OUTCOME

All surface preparation and coating works were completed within the given timeframe, with further coatings work from Chemco still to come on the vessel.

BENEFITS

• Solvent-free

• No grit blasting required

• Excellent chemical and temperature resistance

• Long-term protection from corrosion in alkaline conditions

• Reduced overall project cost and downtime

• Reduced Health & Safety risk and Fire Hazard

• Environmentally-friendly