CASE STUDY

Floating Tank Roofs – BP

Client: BP

Industry: Petrochemical

Scope: Floating Tank Roofs

Date: 2003-ongoing

Location: Kinneil, Finnart and Dalmeny

Products: RL 500PF

OVERVIEW

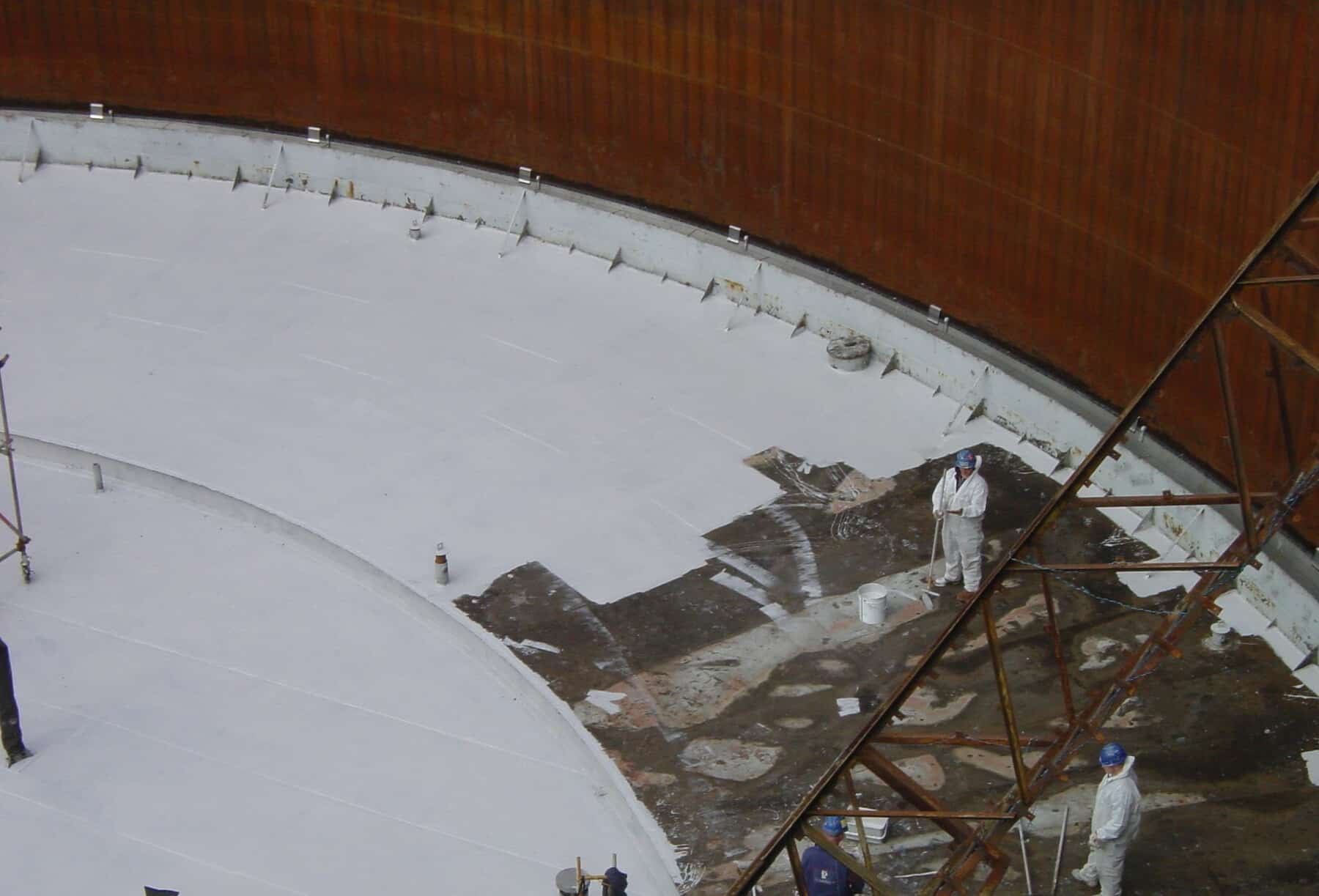

A number of floating tank roofs at BP Kinneil, Finnart and Dalmeny have been refurbished since 2003 utilising Chemco’s unique coating solution.

This case study will focus on a 4,000m² floating tank roof at BP Kinneil which required a complete refurbishment. This project was carried out by Hertel.

CHALLENGE

The wintry condition of low temperatures, high humidity and showers made these projects a difficult job for the originally specified 3-coat epoxy paint system.

A work package of 24 days had been allowed to complete the project.

SOLUTION

Following many other successful applications by the site contractor, Epo-chem™ RL 500PF was put forward as an alternative and accepted by the BP project team.

The tank roof was high pressure washed to remove salt deposits and other contaminants, and the areas of heavy corrosion were spot blasted or mechanically prepared down to metal. Spot blasted areas were coated with 1 coat of Epo-chem™ RL 500PF at 150μm DFT. Standing water was removed and 2 full coats of Epo-chem™ RL 500PF at 150μm was applied overall by brush roller or spray.

OUTCOME

During the contract, the freshly coated areas experienced many occasions of heavy rain and many puddles of cold water forming within hours of application.

The RL 500PF coating was left untouched to cure underwater without the necessity of ANY remedial work and a Chemco guarantee of 16 years was issued, despite the curing condition.

The planned 24 day program was completed in 12 days, offering a huge cost savings as compared to the usual delays due to bad weather.

Since the successful completion of this contract, RL 500PF has been specified for a number of other tank roofs, tank externals and pipe work in Grangemouth, Dalmeny, Finnart and Kinneil, all with complete success.

BENEFITS

- Wet and rust tolerant

- Any surface preparation can be utilised (abrasive blasting, water jetting or mechanical)

- Can be applied and operated in temperatures up to 150°C

- No humidity or dew point restrictions

- No recoating limitations

- Good UV resistance and colour stability

- Can be applied in any environmental condition