CASE STUDY

Heat Exchanger Cooler Repair – Alcotec

OVERVIEW

A number of water coolers, as part of a larger Heat Exchanger Unit, were showing clear signs of operational damage and required to be refurbished for safe use in the future.

This project was carried out by Alcotec.

CHALLENGE

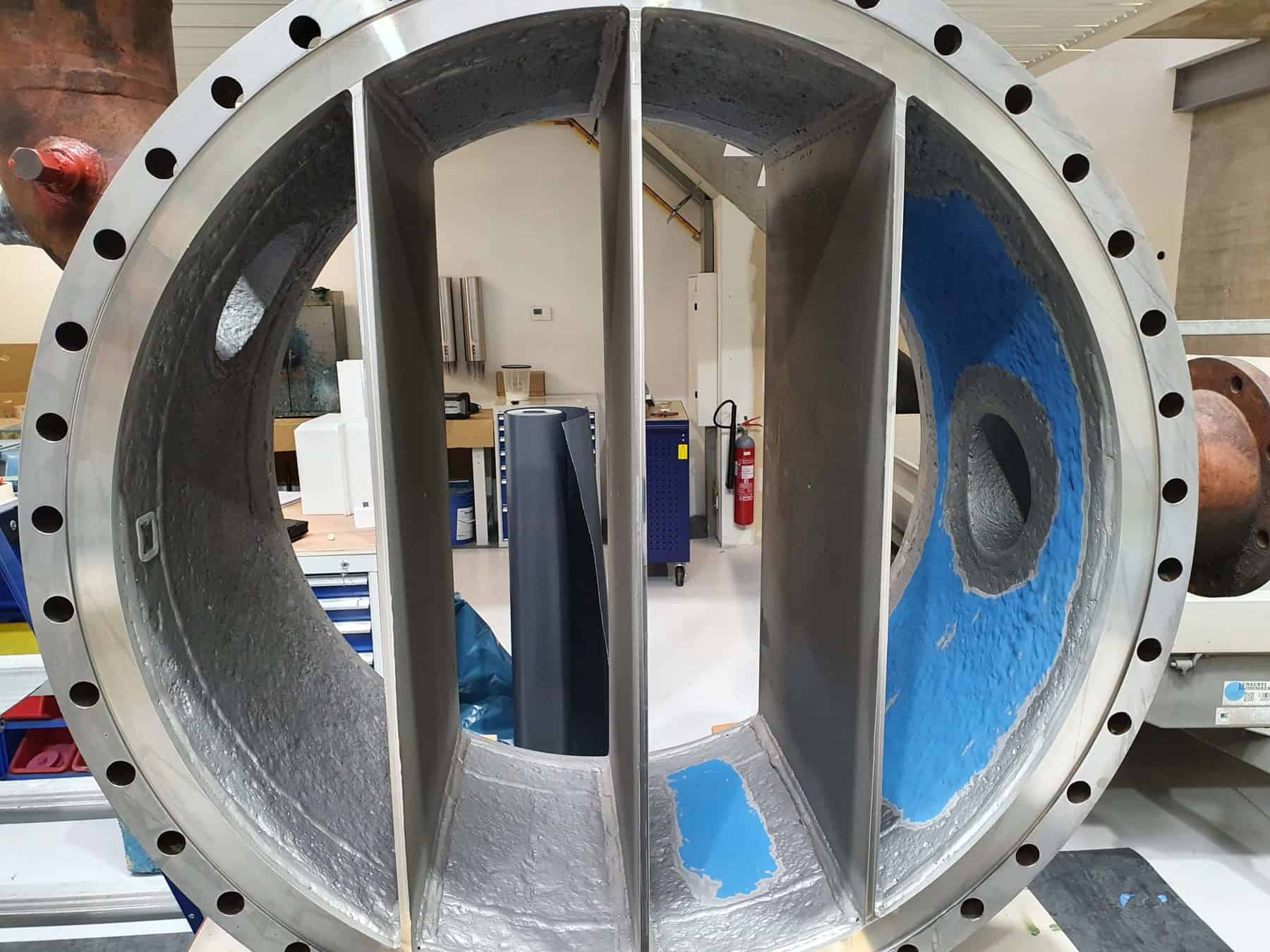

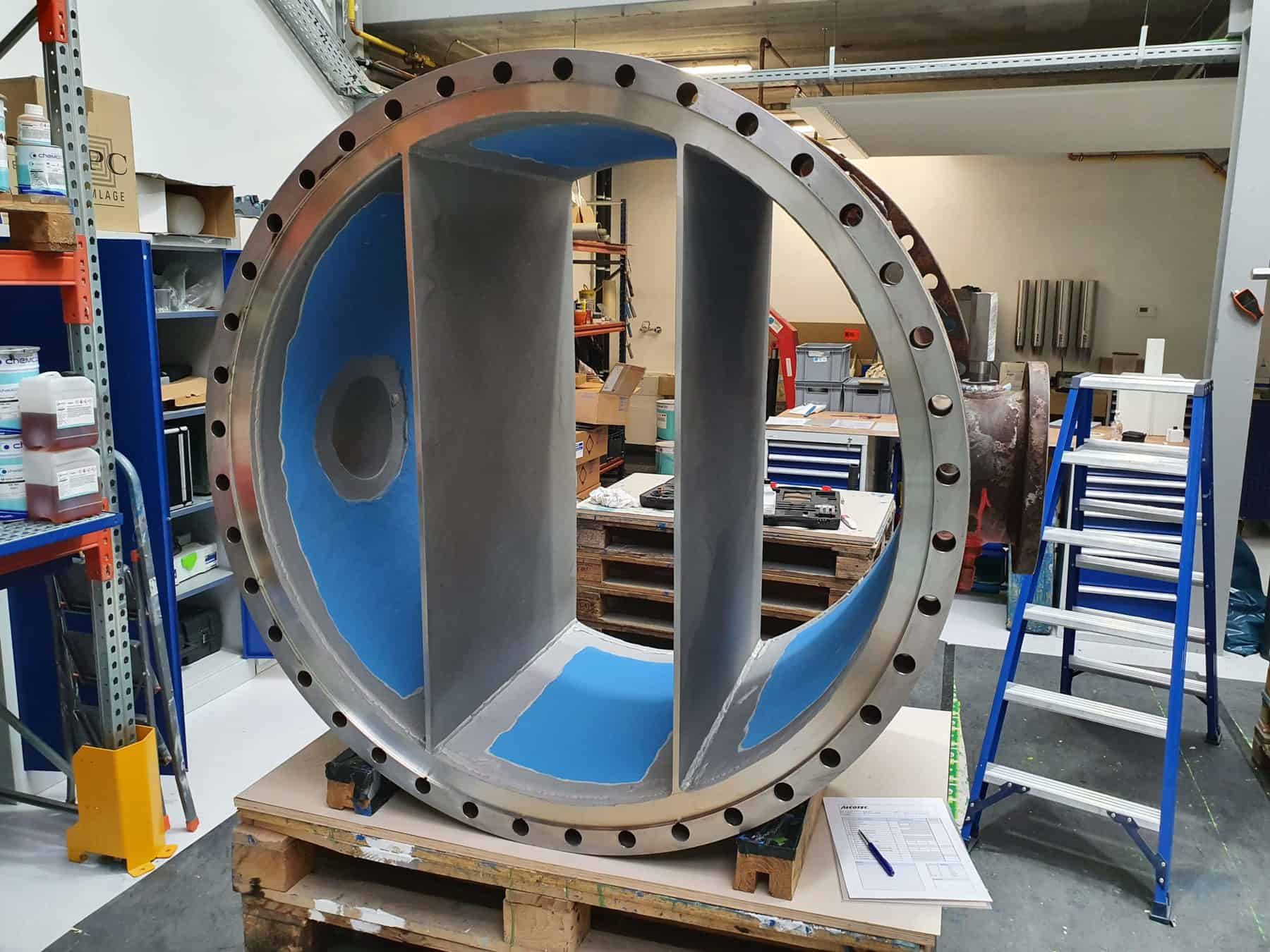

The water cooler components required to be cleaned, welded, repaired and prepared before coating works could begin.

The chosen coating solution had to provide long term protection in an abrasive environment exposed to high fluid flow.

SOLUTION

After all welding and repair works were completed, the water coolers were grit blasted.

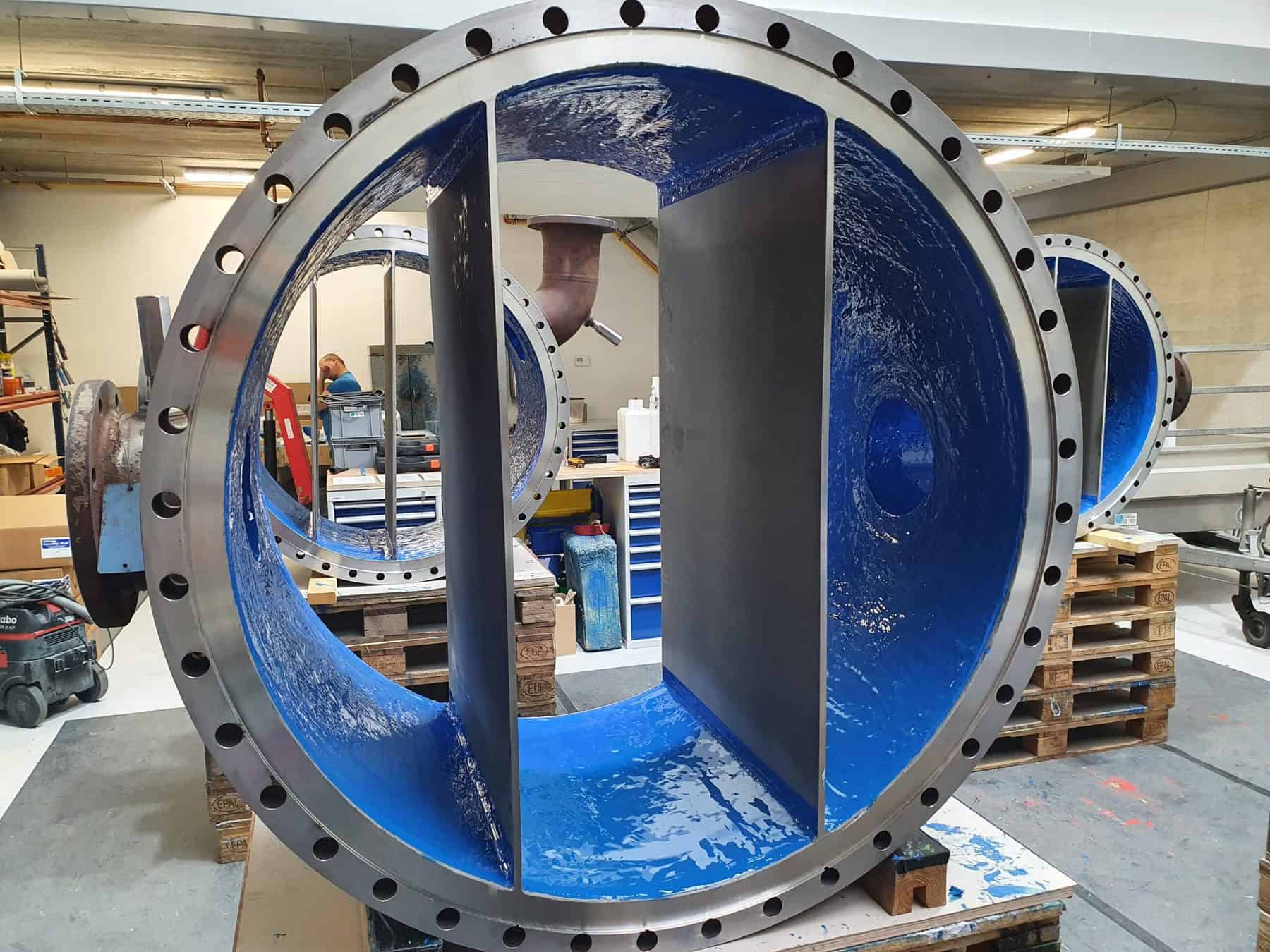

Three coats of solvent-free, ceramic coating RP 500 were then applied in alternating colours to help achieve the required film thickness.

Any areas of pitting were filled by solvent-free, ceramic putty RH 500.

OUTCOME

All coating works were completed on time, within budget and the water coolers were returned to service for a further 6 years.

BENEFITS

• Solvent-free

• Ceramic coating ensures long term abrasion resistance and protection from corrosion

• Excellent chemical resistance

• No recoating limitations

• Easy to apply

• Aesthetically-pleasing finish

• Suitable for