CASE STUDY

Hot Water Tank Lining – Corroless Eastern

OVERVIEW

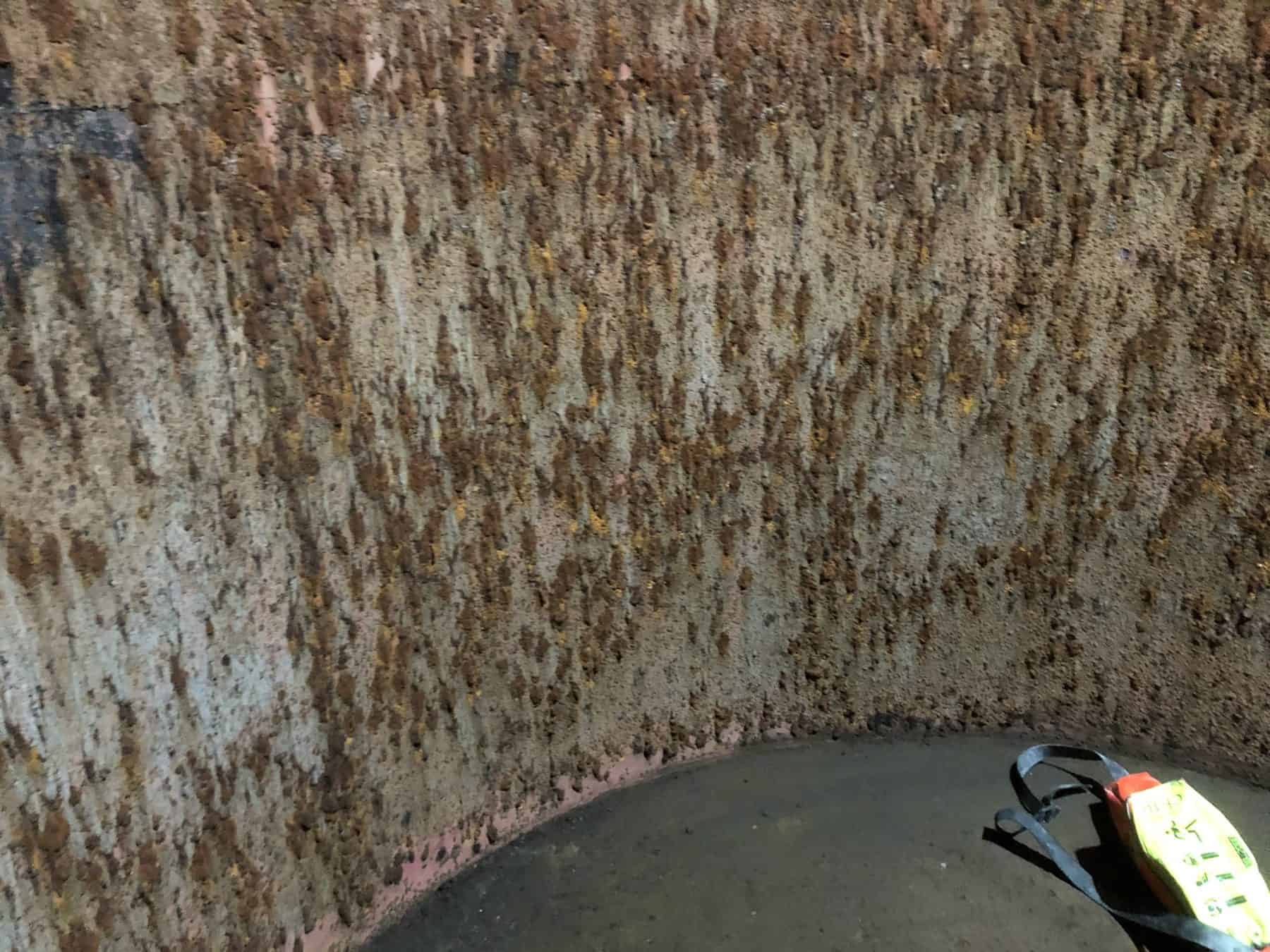

The sealing membrane at the top of the steel hot water tank had burst, allowing oxygen to enter the vessel, leading to corrosion of the tank’s internal structure.

The tank required to be refurbished with a new coating solution that would provide long-term performance.

This project was carried out by Corroless Eastern.

CHALLENGE

The chosen coating solution had to effectively withstand the tank’s operating temperature of around 80°C.

SOLUTION

The tank internals were thoroughly cleaned using high pressure washing, before being sponge blasted to Sa 2½ to achieve the desired surface profile (min. 75μm).

The use of sponge blasting all but eliminated the release of dust into the plant room, which in turn helped to protect the surrounding plant and equipment.

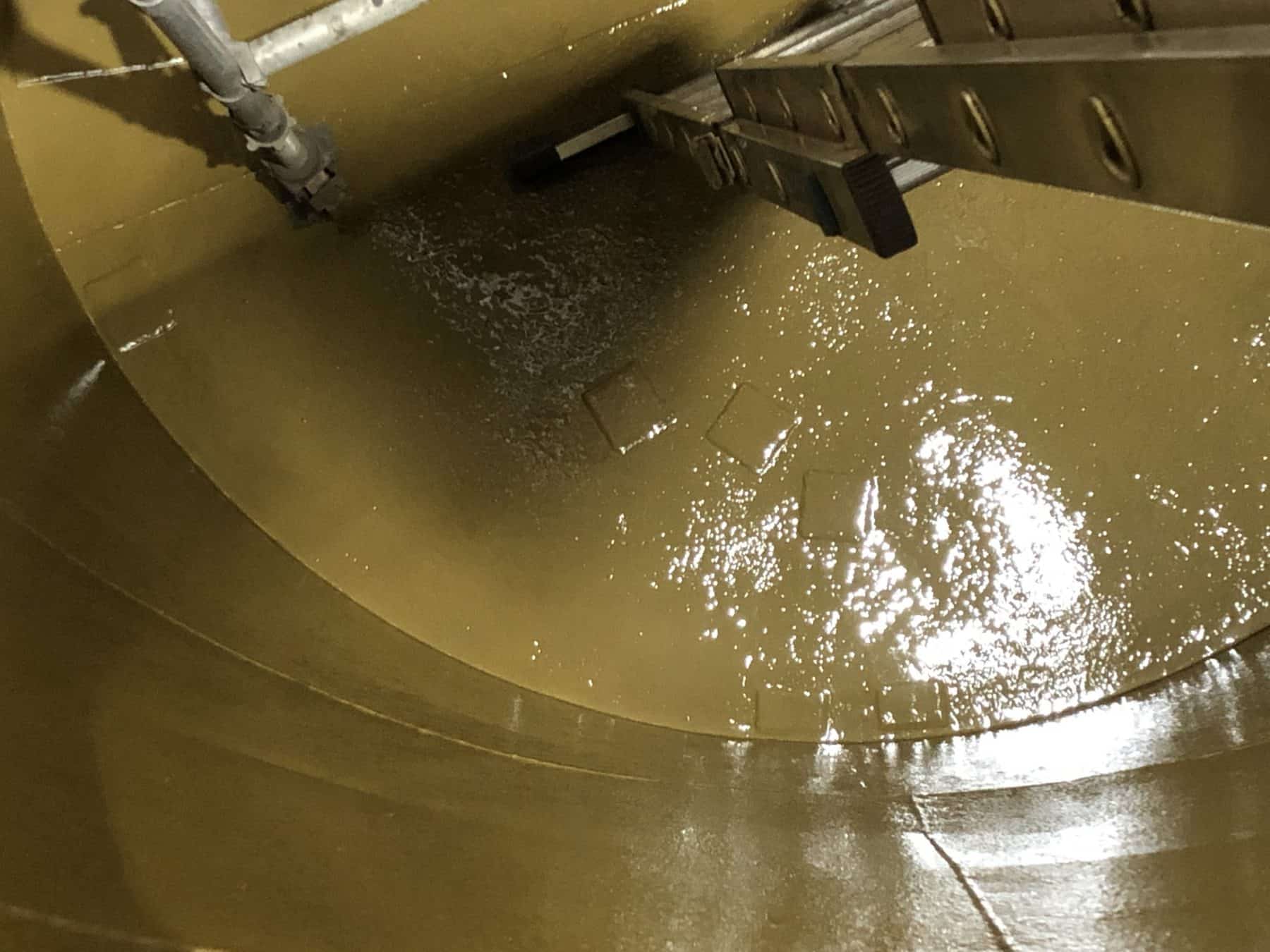

One stripe coat and one full coat of RE 500P was then applied, before one stripe coat and two full coats of RW 500.

OUTCOME

The required DFT was comfortably achieved and the works were warranted for 10 years from completion.

BENEFITS

- Solvent-free

- Zero VOC

- Exceptional chemical and high temperature resistance

- Exceptional surface tolerance and corrosion resistance (glassflake-reinforced)

- No grit blasting required

- Fast curing and quick recoating

- Reduced contract duration and downtime