CASE STUDY

Hot Well Tank

OVERVIEW

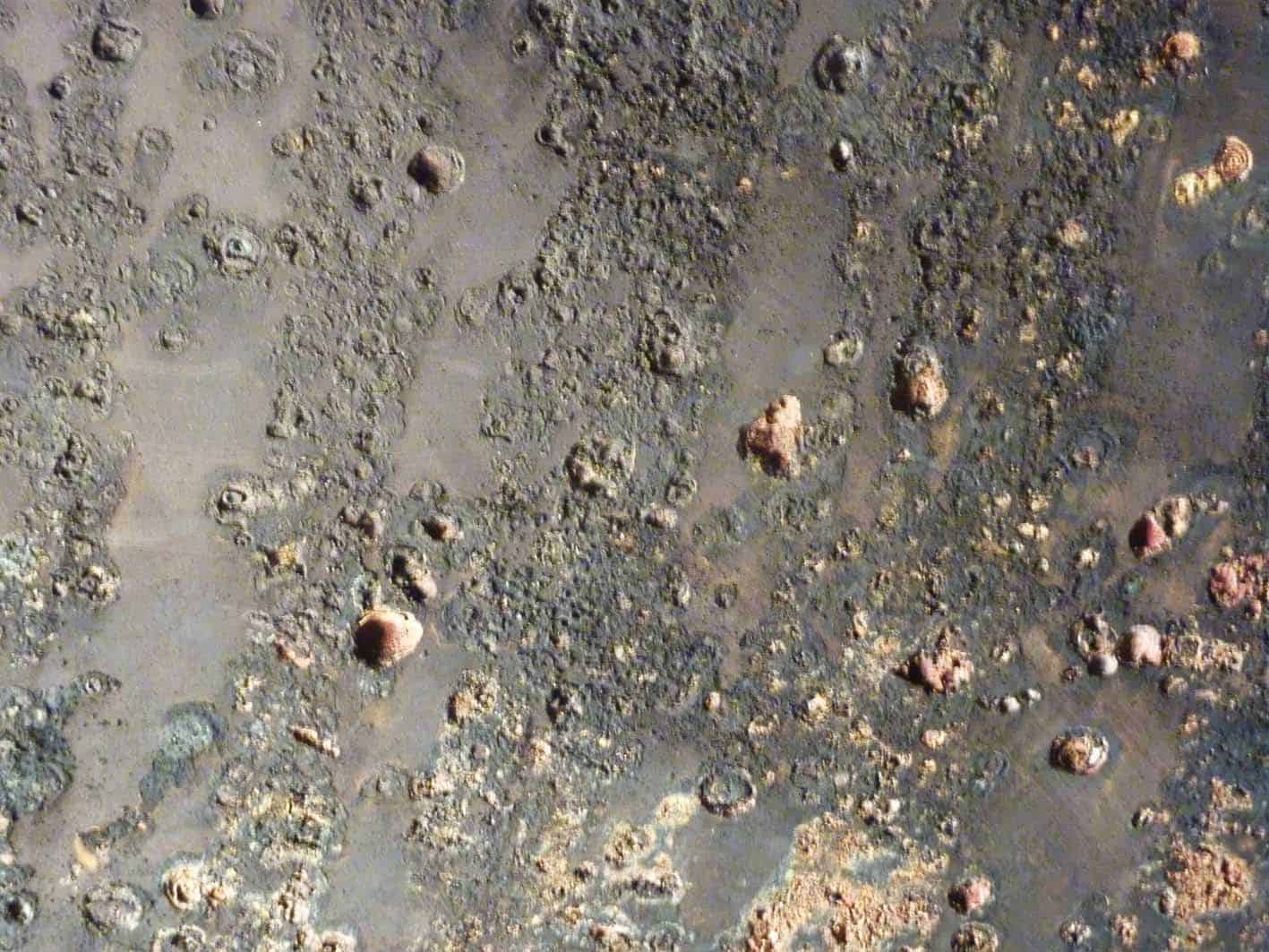

Kenross Containers were looking for a tank lining system suitable for temperatures up to 85ºC for one of their hot well tanks. The areas below the water level were suffering from advanced corrosion and very deep pitting after only a few months in service. This project was carried out be Specialist Coatings UK.

CHALLENGE

Working at heights with narrow access into the tank. The short time frame given to complete this project also added to the difficulty.

SOLUTION

The tank internals were abrasive blasted to Sa 2.5 standards, followed by final cleaning of the prepared surfaces by an industrial vacuum. One coat of solvent-free, rust tolerant, high temperature resistant, epoxy Novolac primer Epo-chem™ RE 500P was applied. Epo-chem™ RW 500 solvent-free, glassflake reinforced, Novolac epoxy topcoat system was then applied.

OUTCOME

The work was carried out on time, with no delays to the project. The finish of the Chemco system was to the satisfaction of all concerned and has extended the working life of the tank by an anticipated 15 plus years.

BENEFITS

• Solvent-free

• Excellent chemical and high temperature resistance

• No major delays

• Fast-curing and quick over-coating

• High gloss finish