CASE STUDY

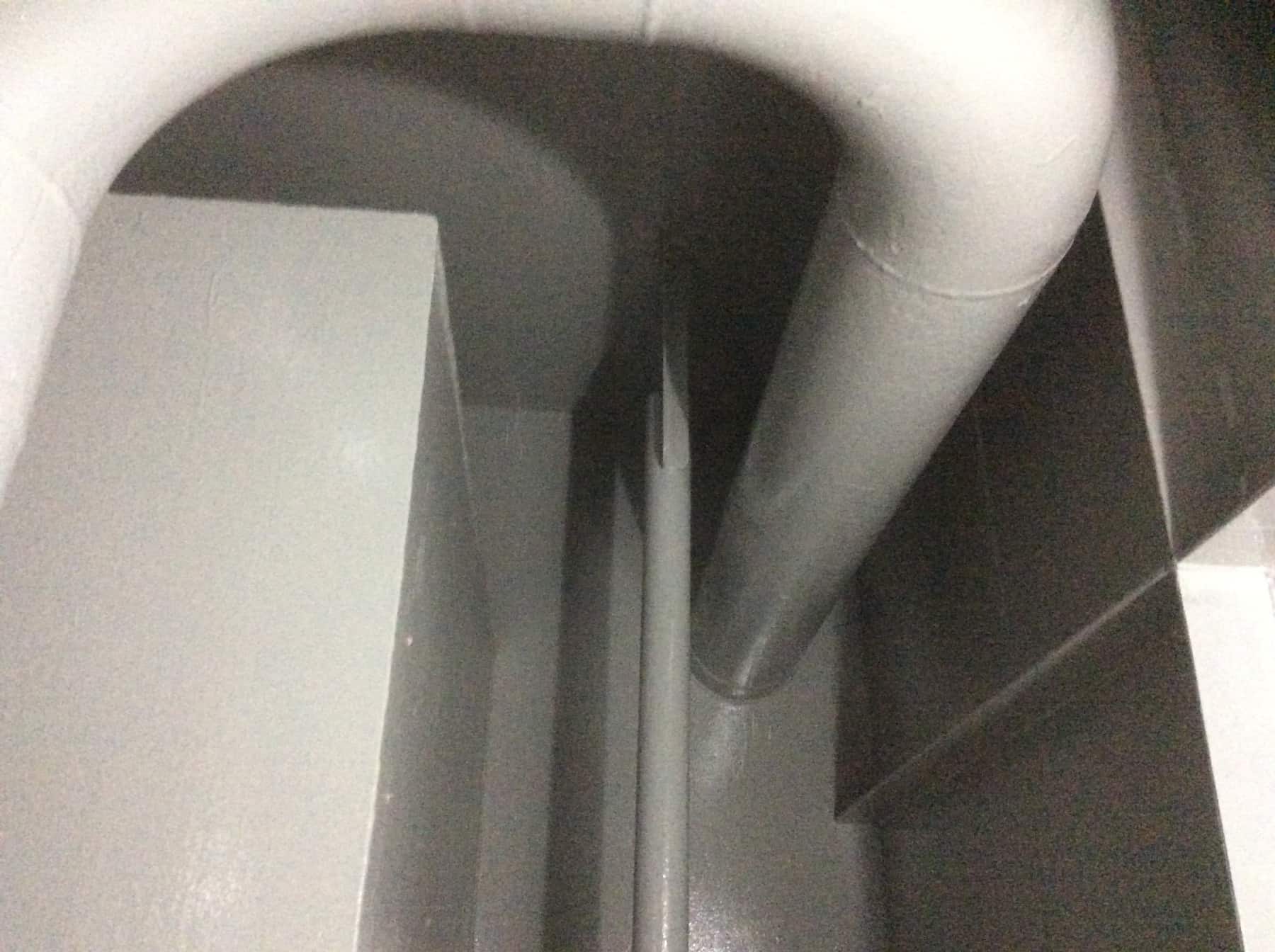

Hot Well Tank

Client: Carnival

Industry: Marine

Scope: Hot Well Tank

Date: February 2015

Location: Australia

Products: RW 500

OVERVIEW

A hot well tank on-board the Passenger Ship required a protective coating system capable of handling hot water at temperatures around 90ºC. This system also had to be applied on new shop primed steel.

CHALLENGE

The client required a coating system which could be applied without the removal of the shop primer as grit blasting was not permissible. There was also a strict time frame to complete the project.

SOLUTION

The surfaces were freshwater washed and degreased to remove any contamination from the substrate. This was followed by one stripe coat and one full coat of solvent-free, wet tolerant epoxy Epo-chem™ RW 500.

OUTCOME

The unique wet tolerant properties of Epo-chem™ RW 500 system ensured that the coating application could take place immediately upon surface preparation completion. Moreover, the shop primer did not require to be removed before the Chemco system could be applied as the systems were 100% compatible. Substantial time and cost savings were achieved by utilising this Chemco system.

BENEFITS

• Solvent-free

• Compatible with shop primed surface

• Can be applied on soaking wet surfaces

• Reduced downtime

• Excellent chemical and high temperature resistance

• No grit blasting

• Reduced H&S and Fire Precautions

• Fast-curing and quick over-coating