CASE STUDY

Potable Water Tank Repair

OVERVIEW

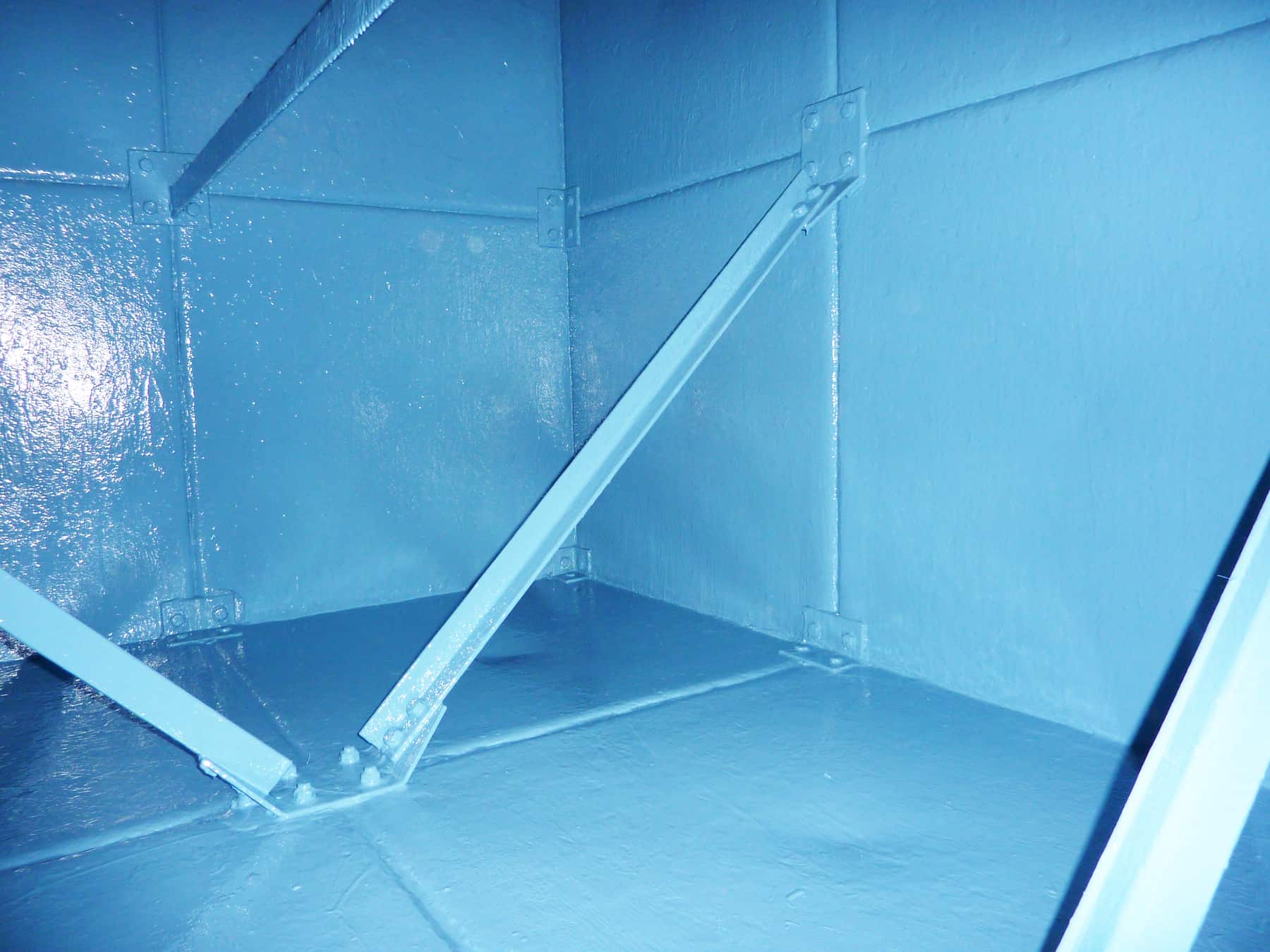

The hospital’s Braithwaite panel tank was in an extremely poor condition as the existing bitumen coating had completely failed.

CHALLENGE

There could be no disruption to others working nearby. Noise and dust levels had to be kept to a minimum. Work could only be carried out within restricted hours. There was also a tight time schedule to complete the work.

SOLUTION

Manual preparation was selected as the surface preparation method. One primer coat of solvent-free, wet & rust tolerant Epo-chem™ RS 500P was applied first. This was followed by two topcoats of solvent-free, wet tolerant Epo-chem™ RA 500M.

OUTCOME

The work was completed within 5 days with the tanks being restored to “as good as new” condition. The unique Chemco system allowed the work to be carried out without disruption to others working nearby. This system is NSF Certified for fresh drinking water applications.

BENEFITS

• Solvent-free

• Restored to “as good as new” condition

• No operational shutdown

• Reduced H&S and Fire Precaution

• No grit blasting

• Substantial time and cost savings