CASE STUDY

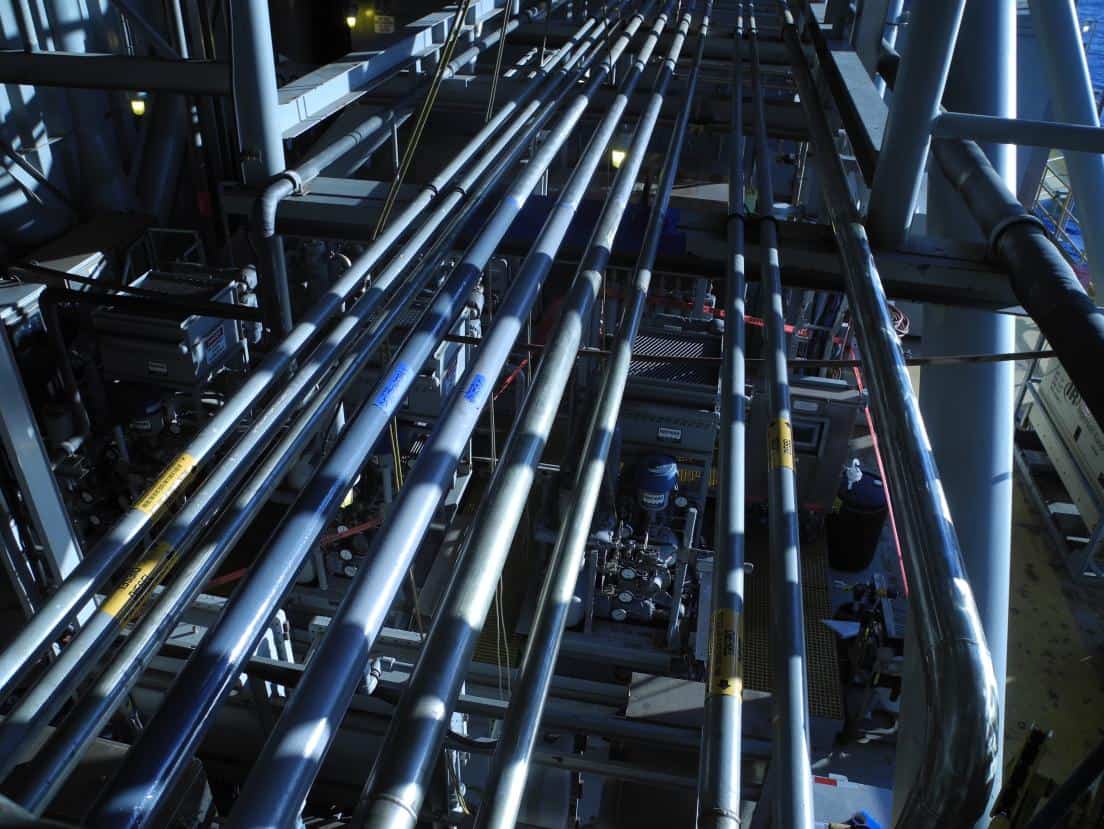

Stainless Steel Piping – Offshore Platform

Client: Offshore Platform

Industry: Offshore

Scope: Stainless Steel Piping – Offshore Platform

Date: November 2012

Location: Gulf of Mexico

Products: RL 500PF

OVERVIEW

The operators of an offshore platform in the Gulf of Mexico were dissatisfied with the performance of the coating system they were utilising for stainless steel pipes. As a result, new paint trials for two alternative coating systems against the current system were to be carried out.

CHALLENGE

The coating systems had to have high adhesion to the stainless steel substrate, with minimal surface preparation. Application would be carried out in adverse weather conditions and in very high humidity.

SOLUTION

For accurate comparisons to be compiled, the surface preparation method (mechanical) and application conditions were to remain constant for all three systems.

Chemco’s unique wet & rust tolerant primer/finish Epo-chem™ RL 500PF was applied to the mechanically prepared surface in one coat. The current system was applied in three coats, whilst the other alternative system was applied in two coats.

OUTCOME

The Chemco system was applied in the shortest time and offered the longest pot life. There are also no humidity or dew point restrictions with the Chemco system. Upon completion of the trial, the client stated that their product of recommendation would be Chemco’s Epo-chem™ RL 500PF. After two years of service the project was inspected and the coating inspector stated that the Chemco system was still in perfect condition.

BENEFITS

• Wet & rust tolerant properties of Chemco system

• Application in any environmental conditions

• Primer/finish in one coat

• No humidity or dew point restrictions

• No over-coating limitations

• Reduced application time