CASE STUDY

Sweating Pipeline Refurbishment – Offshore

OVERVIEW

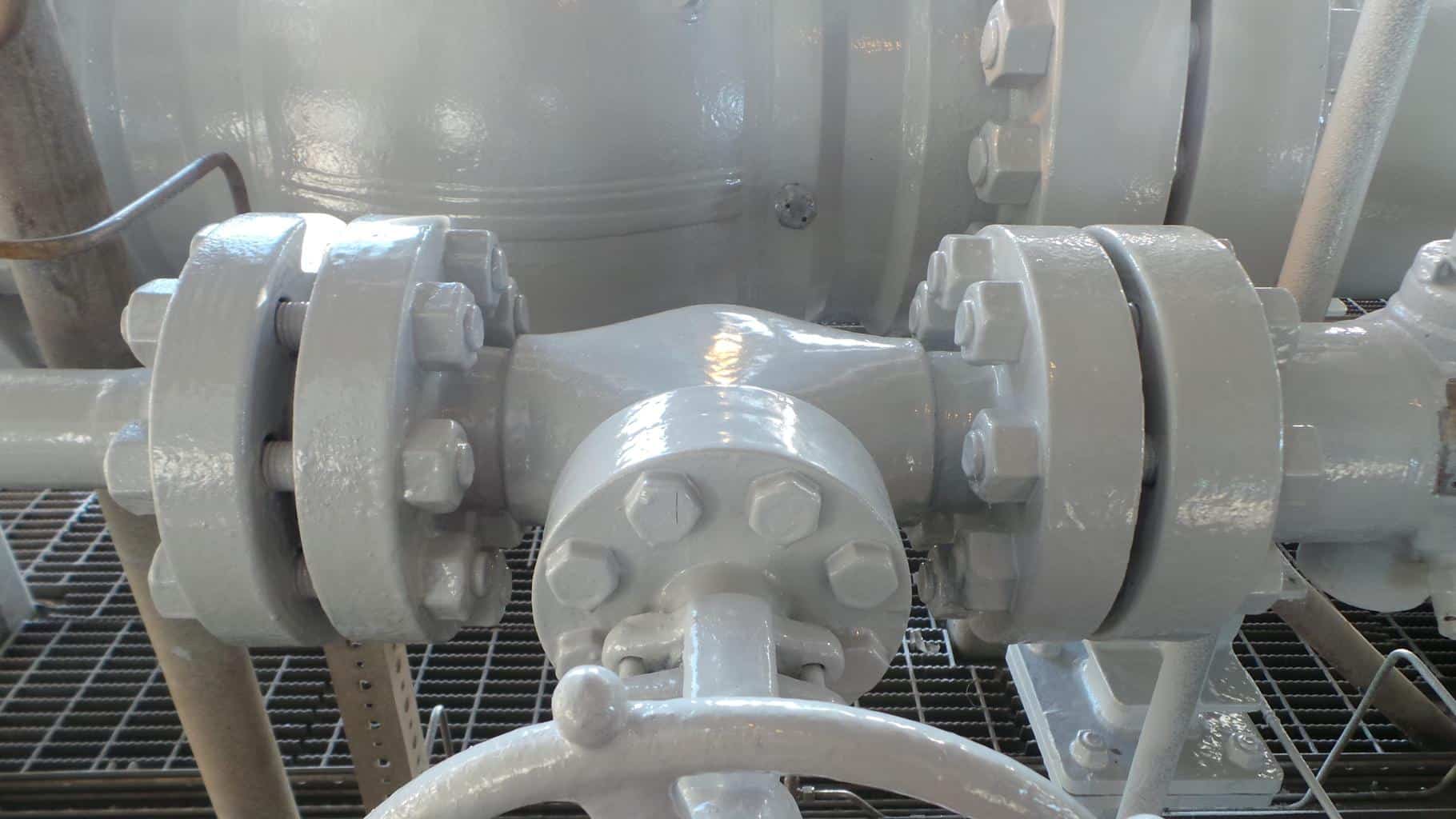

A corroded meter skid consisting of 16″ sweating pipeline and 14″ pipeline (along with riser) required a corrosion protection system with minimal surface preparation which could be applied to both wet and dry substrates.

CHALLENGE

Working in the Gulf of Mexico with humid weather conditions combined with constantly wet “sweating” substrate.

SOLUTION

One coat of solvent-free, wet and rust tolerant epoxy primer RS 500P was applied at 150 microns DFT, followed by one coat of solvent-free, wet tolerant glassflake epoxy RA 500M at 250 microns.

Application was done by brush, roller and spray.

OUTCOME

The major technical benefits offered by utilising this system ensured that the work was carried out safely, on time and with no delays to the program on both wet and dry substrates.

BENEFITS

- Solvent-free

- No grit blasting required

- No delays due to weather or sweating substrate

- Application carried out on sweating pipe without shutdown

- Short recoating intervals between primer (RS 500P) and finish coat (RA 500M)

- Reduced cost of labour and surface preparation

- Long-term asset protection