CASE STUDY

Water Cooler Repair – Alcotec

Client: ENGIE

Industry: Power Generation

Scope: Water Cooler Repair

Date: May 2019

Location: Belgium

Products: RP 500

OVERVIEW

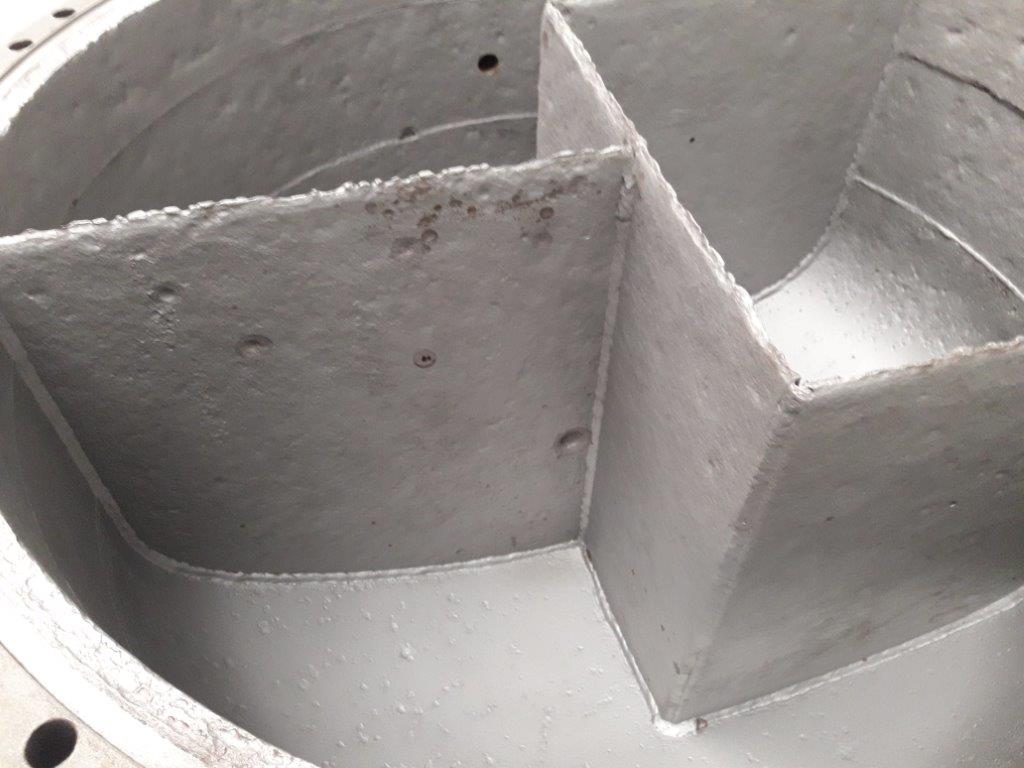

During revision works at a power station, a water cooler was dismantled and severe corrosion was observed.

CHALLENGE

The baffle plates of the cooler had to be cleaned and rebuilt by welding and CNC machining, before being coated with a system that would provide long term corrosion protection.

The coating solution had to protect the carbon steel from the likely exposure to galvanic current within the plant.

SOLUTION

The cooler was cleaned by grit blasting. The welding and machining then took place in order to seal the surfaces areas.

Due to its ability to resist very aggressive fluid flow environments, three coats of solvent-free ceramic coating Ceram-chem™ RP 500 were then applied.

OUTCOME

The water channel was completely restored, allowing the cooler to return to full operation.

The project was completed on time and within budget.

BENEFITS

• Solvent-free

• Robust ceramic technology providing a hard wearing, abrasion-resistant impermeable barrier

• Suitable for repair work on all types of fluid flow equipment

• No recoating limitations

• Easy to apply

• Provides long term corrosion protection