CASE STUDY

Absorber Sump Repair – South Korea

OVERVIEW

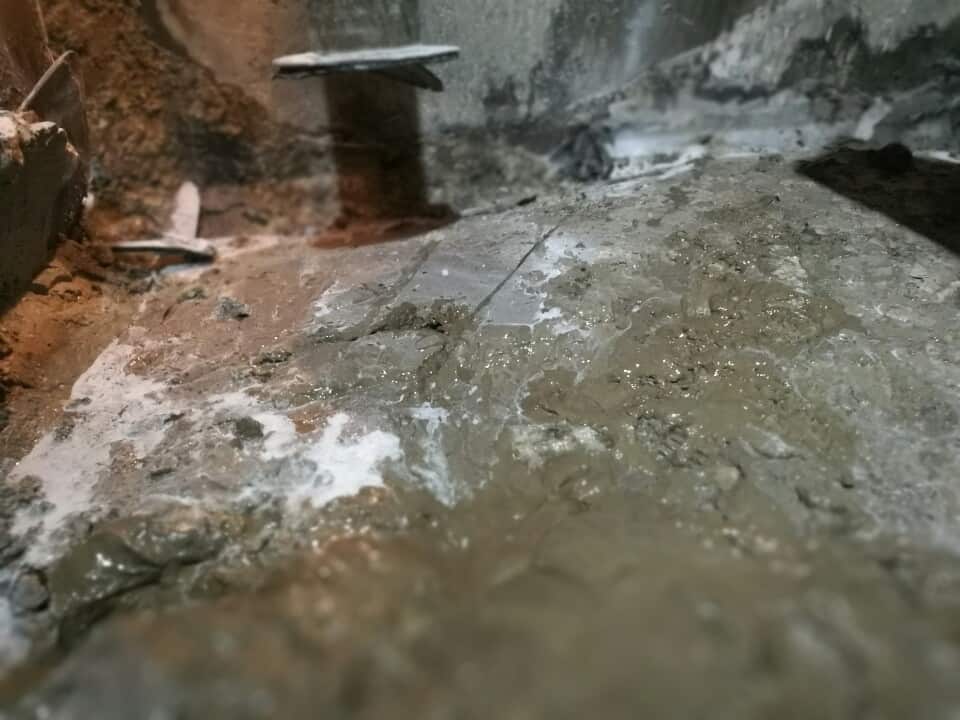

The FRP lining of the concrete sump within an FGDS absorber tower was suffering from delamination of the lining due to poor adhesion and abrasion from limestone slurry.

After repeated attempts to reline the sump, the client was looking for an alternative coating system which would provide effective long-term adhesion and abrasion resistance.

CHALLENGE

The concrete sump was situated within a confined space, making access and good working practices difficult to perform. Grit blasting was not permissible.

The refurbishment had to be completed within 6 days.

SOLUTION

The lining was removed using a combination of water jetting and mechanical preparation with grinders. The damaged areas and cracks within the concrete were part-repaired with the necessary putties and injection systems.

One coat of solvent-free, wet tolerant concrete primer RH 800 was then applied. This was followed by one coat of solvent-free, glassflake epoxy Novolac RW 500.

OUTCOME

The project was completed on time and in an efficient manner thanks to the time and cost-saving benefits of the chosen Chemco system.

BENEFITS

| RH 800 | RW 500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|