Applications

Ceramic Coatings

OVERVIEW

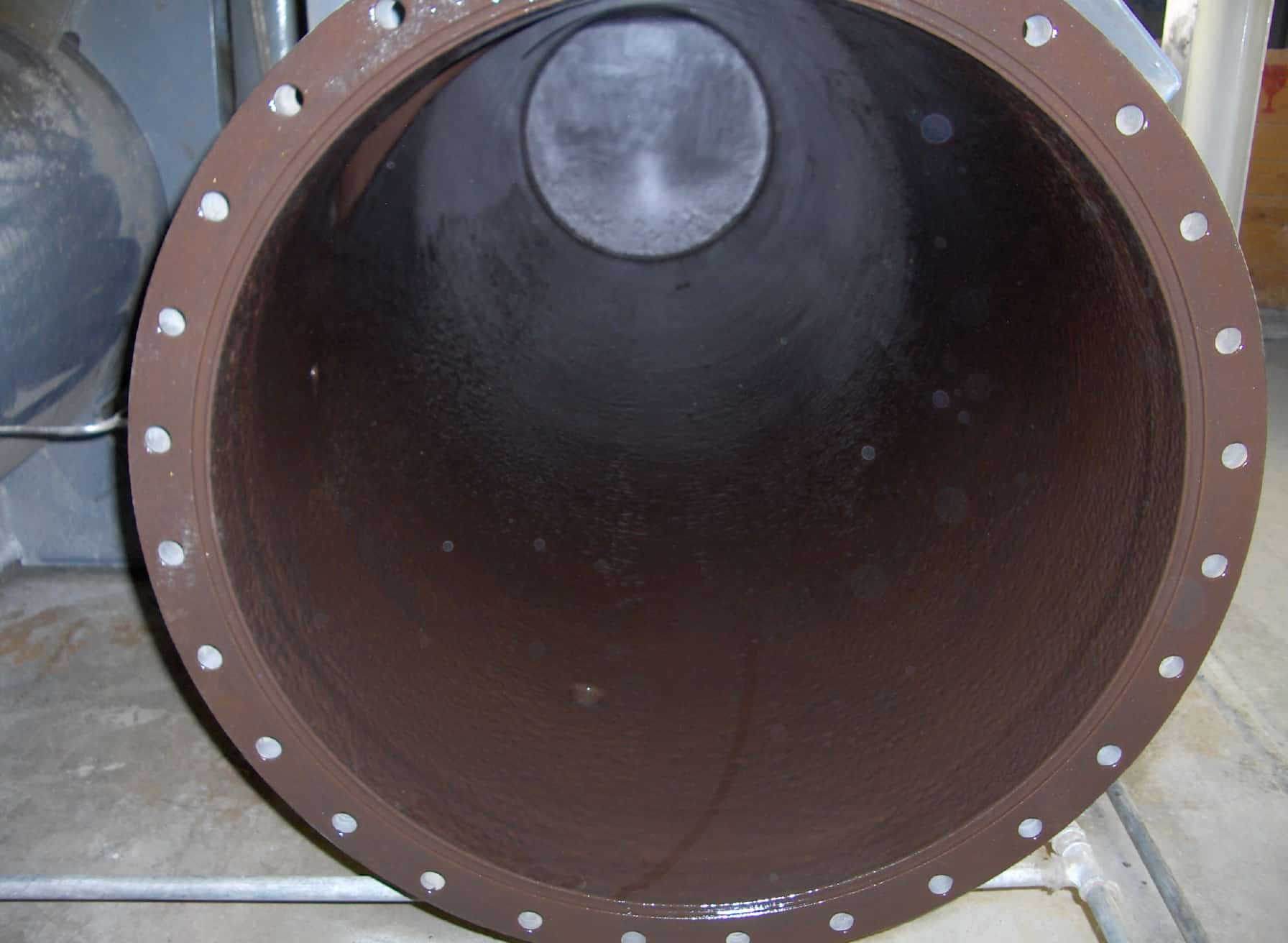

Chemco’s range of ceramic coatings are designed using a blend of ceramic and epoxy technologies that are ideal for the repair and protection of process equipment used in highly abrasive or high fluid-flow applications.

BENEFITS

These systems are categorised based on their chemical and temperature resistance; ranging from ambient temperature and mild chemical resistance, to high temperature and aggressive chemical resistance.

They exhibit the following characteristics:

- Solvent-free

- Styrene-free

- Excellent abrasion/cavitation resistance

- Excellent chemical resistance

- Improved equipment efficiency

SOLUTIONS

Product Gallery

SOLUTIONS

Mild Chemical Resistance / Ambient Temperatures

A high density, solvent-free epoxy filler/putty/renewal compound designed to fill/repair cavities, cracks and heavy pitting.

This product is specifically formulated for repair of all fluid-flow equipment as a filler/build-up coat. The material cures rapidly to form an extremely tough, machinable finish with excellent resistance to abrasion and cavitation.

It is designed for applications where temperatures may be up to 80°C. It can then be machined to the required thickness/tolerance prior to application of topcoats such as RP 500 or RU 500 . It is very easily applied by trowel, spatula or brush to any thickness or depth without cracking.

When a rust tolerant primer is required, RS 500P is fully compatible with RH 500.

A two pack, solvent-free, ceramic epoxy topcoat which provides an extremely hard wearing, very smooth, low friction surface for all fluid-flow environments.

This product has an excellent chemical resistance and is used for general chemical environments, such as petroleum or sea water.

It is designed to handle temperatures up to 70°C, and is easily applied by brush, roller or airless spray (in specific circumstances). It has FDA approval for drinking water and food contact, and there are no over-coating limitations.

Deep pitting and voids can be filled quickly with RH 500 metal repair compound.

RP 500 is fully machinable and has excellent adhesion with RH 500 filler and RS 500P if a rust tolerant primer and topcoat only is required.

SOLUTIONS

Aggressive Chemical Resistance / Mid-range Temperatures

A two pack, solvent-free, high density, high temperature Novolac epoxy putty designed to fill cavities, cracks and heavy pitting.

Cerpofix™ renewal compound is specifically formulated to rebuild all types of fluid flow equipment as well as general-purpose rebuild/filling/repairs.

The material cures rapidly to form an extremely tough machinable finish which is easy to apply.

It is recommended that this product is used in conjunction with RE 500P (Primer) and RU 500 Hi-performance topcoat for a complete repair system.

A two-pack, solvent-free ceramic epoxy Novolac topcoat which has similar qualities to RP 500 in that it provides a very smooth, low friction surface.

It is ideal in extremely corrosive environments and offers excellent resistance to the combination of aggressive chemicals and high temperatures up to 130°C. It may be applied by brush, roller or airless spray (in specific circumstances).

Deep pitting and voids can be filled quickly with epoxy novolac RW 500.

SOLUTIONS

Highly Aggressive Chemical Resistance / High Temperatures

A two-pack, solvent-free, high temperature epoxy putty, designed to fill cavities, cracks and heavy pitting.

This product is specifically formulated for repair and renewal of all types of fluid-flow equipments operating at temperatures up to 250°C, and offers an extremely tough machinable finish with excellent resistance to abrasion and cavitation.

It is then machined to the required thickness/tolerance prior to the application of the topcoat RF 900 series.

It is very easily applied by trowel, spatula or brush to any thickness or depth without cracking.

A high temperature, two-pack, solvent-free, ceramic epoxy topcoat which can be used in situations where there is a combination of very aggressive chemicals and very high temperatures up to 220°C.

It is an extremely hard wearing, very smooth, low friction surface for repair and renewal of all fluid-flow environments operating at high temperatures.

It can be applied by brush, roller or airless spray (in specific circumstances).

A solvent-free, low odour, three pack epoxy Novolac compound incorporating a blend of ceramic filler & beads.

This product is especially formulated for fluid-flow equipment, hoppers, nozzles, chutes, vessels, pipe bends and deflector plates, etc.

It is recommended to be used in conjunction with RE 500P (Primer) and RU 500 Hi-Performance composite (topcoat/sealer) for a complete repair system.