NEWS

Chemco’s Smart Solution for Scrubber Systems

With strict Sulphur Oxide (SOx) regulations set to be enforced by the International Marine Organisation (IMO) in 2020 – dictating a global cap of 0.5% SOx emissions – almost all major shipping companies are undergoing fundamental operational changes in order to comply and avoid the significant financial and environmental drawbacks that would otherwise occur.

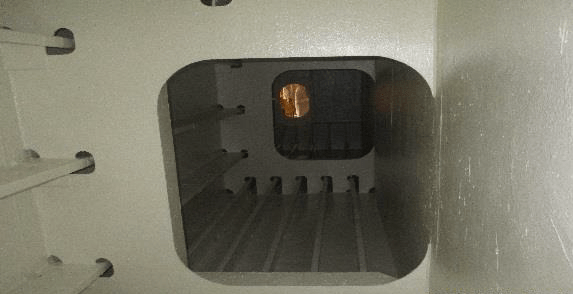

As a result, the use of scrubber systems is becoming increasingly more common in the marine industry. Scrubbers operate by passing these harmful SOx exhaust gases through certain control devices, progressively cooling the gases until the end result is a neutralised solution that can be disposed of without providing any harm to the environment or marine life. The complexity of these scrubbers and their ever-growing importance in the market emphasises the need for high quality, long-lasting coating solutions.

Chemco offer a coating solution for scrubbers which comprises two key systems; one ensuring a highly chemical resistant coating suitable for high temperatures and strongly acidic environments, and the other an innovative solvent-free, wet & rust tolerant solution.

System 1:

System 2:

Chemco’s specialist coating systems provide excellent solutions for the open and closed loop systems for all scrubber tanks & pipes; ensuring considerable time, cost and environmental savings. System 1 is used in all areas exposed to high temperatures and where aggressive acids are present; notably the scrubber unit and residence/process tanks. System 2 can be utilised once the tank residues have been neutralised; notably in discharge pipes and settling tanks.

These coating systems display a range of distinct benefits that ensure long-lasting service of all areas in the scrubber process.

To find out more about Chemco’s expertise in providing specialised coating solutions for scrubber systems, please get in touch today.

| System 1 | System 2 |

|---|---|

|

Exceptional chemical resistance |

Solvent-free |

| Exceptional resistance to high temperatures |

Any surface preparation method can be utilised |

|

Full pH protection (1-14) |

No humidity or dew point restrictions |

| Provides an impermeable barrier to corrosion |

Quick back-in-service times |

|

Fast curing, which allows quicker recoating intervals and back-in-service times |

No recoating limitations |

| Near smooth finish which can be made in many colours |

No extensive dehumidification requirements |

|

Meets new regulatory standards |

Nearby work can continue without disruption |

| Low maintenance and ease of repairability |

Significantly reduced H&S concerns and Fire Hazard |

| Proven resistance to many thermal ageing and abrasive environments |

Long-term maintenance free performance |

Related Products…

Contact Our Specialist Coating Advisors…

Our coating specialists can suggest the right solution for your specific application.