CASE STUDY

Chemical Tank Internal Refurbishment

Client: BP

Industry: Petrochemical

Scope: Chemical Tank Internal Refurbishment

Date: September 2009

Location: UK

Products: RB 300

OVERVIEW

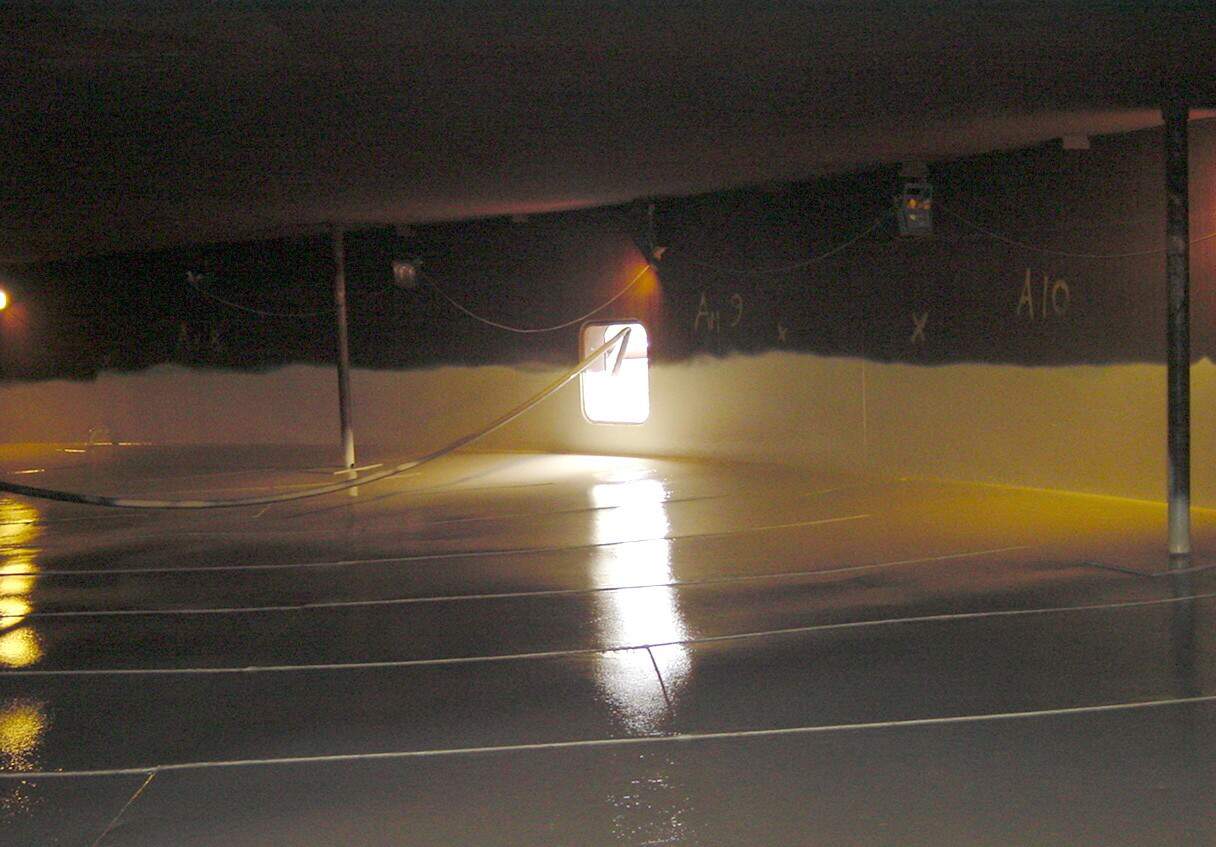

The internal floor area and 1m up the walls of a 44m diameter tank holding reformate, required to be completely refurbished in a limited timescale during the hydrocracker shutdown.

CHALLENGE

Working within a very tight timescale and working in a tank that has suffered from severe pitting and corrosion added to the difficulty of this project.

SOLUTION

First coat of Chem-tect™ RB 364 vinylester system @ 200µ. All relevant areas suffering from severe pitting were then filled with Chem-tect™ RB 300 series vinylester putty. Second coat of Chem-tect™ RB 332 vinylester system @ 400µ. Final coat of Chem-tect™ RB 364 vinylester system @ 200µ.

OUTCOME

The major technical benefits offered by utilising this system assured the client that the work was carried out on time, within budget, with no major delays to the program and no impact on other contractors. Similar tanks on site will now be refurbished utilizing the Chemco vinylester system due to its great success.

BENEFITS

• No major delays to program

• Reduced H&S and Fire Precaution

• Chemco system will protect steel substrate