CASE STUDY

Chemical Tank Refurbishment

– 6 Year Performance Inspection

Client: Shipmanagement Company

Industry: Marine

Scope: Chemical Tank Refurbishment – 6 Year Performance Inspection

Date: 2022

Location: Belgium

Products: RE 500P & RW 500, RB 300 Series

OVERVIEW

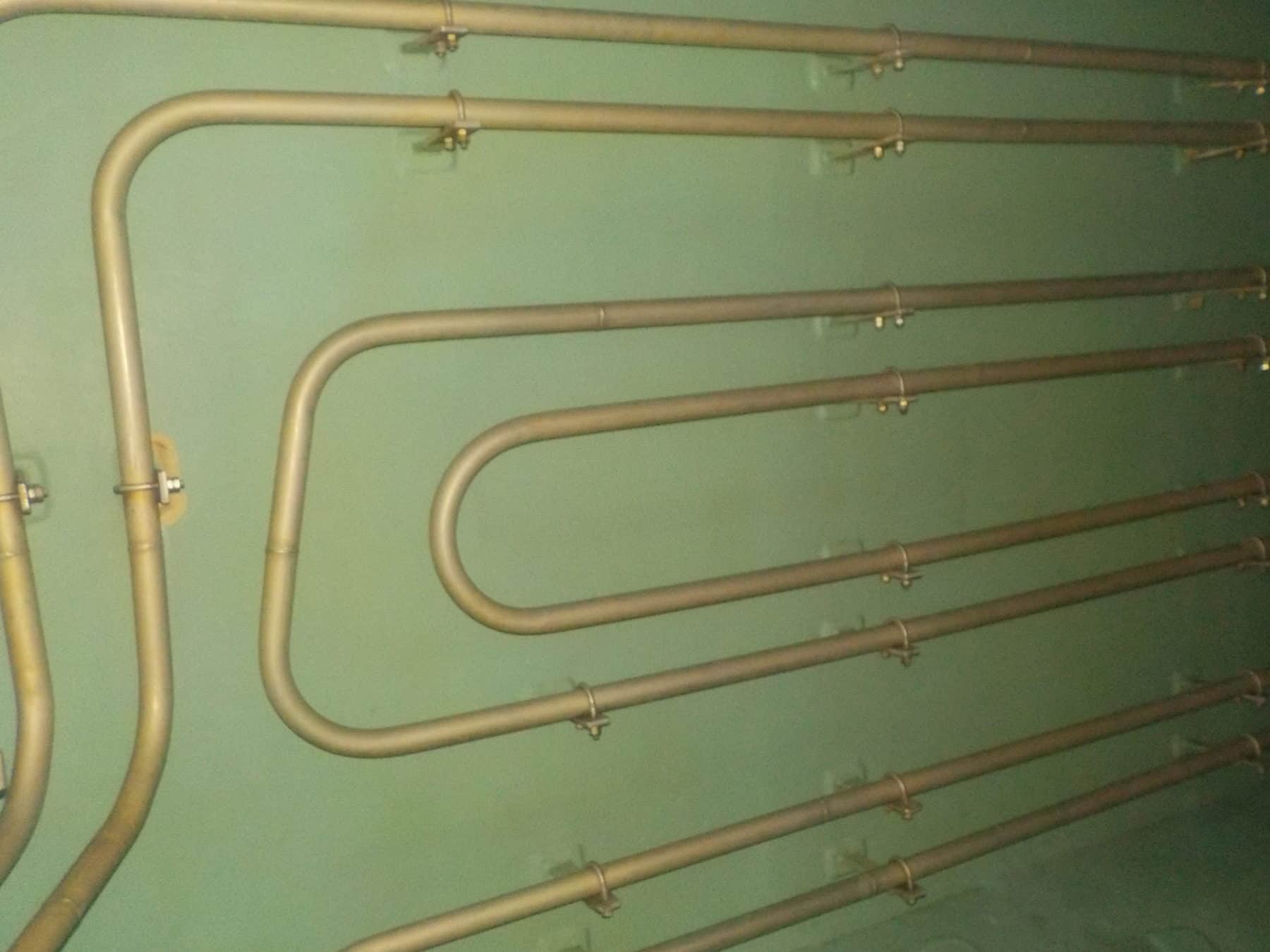

In 2016, a set of chemical tanks onboard a large chemical tanker were refurbished using Chemco’s epoxy Novolac system (RE 500P & RW 500) and Vinylester system (RB 300 Series), as per respective tank specifications.

In 2019, further tanks were refurbished using Chemco’s RB 300 Series.

In 2022, all tanks were inspected to assess the requirement for further repair works.

CHALLENGE

Prior to inspection in 2022, the internal condition of the tanks was largely unknown.

The performance of the previously applied Chemco systems would dictate the requirement for further repair works.

SOLUTION

All tanks were surveyed in early 2022, approximately 6 years and 3 years, respectively, after initial refurbishment works had been undertaken using the Chemco coating systems.

The inspection report found the condition of all tanks coated in Chemco to be generally good, as supported by photographic evidence.

There was minimum rust spotting and coating degradation, said to be caused mainly by mechanical damage; with the worst of the coating breakdown present in the tanks where a different manufacturer’s paint system was used.

OUTCOME

It was decided that the performance of the Chemco coating systems ensured that only further spot repair was recommended, and that no full repair was required.

These repair works were set to take place during the vessel’s upcoming dry dock.

BENEFITS

RE 500P & RW 500

- Solvent-free

- Surface preparation flexibility (no grit blasting required)

- Excellent chemical and temperature resistance

- Long-term corrosion protection in alkaline conditions

- Reduced overall project cost and downtime

- Reduced Health & Safety risk and risk of Fire Hazard

RB 300 Series

- 100% Solid

- Full pH protection (1-14)

- Excellent chemical and temperature resistance

- Provides impermeable barrier between coating and substrate

- Fast curing / quick recoating intervals

- Quick back-in-service times