CASE STUDY

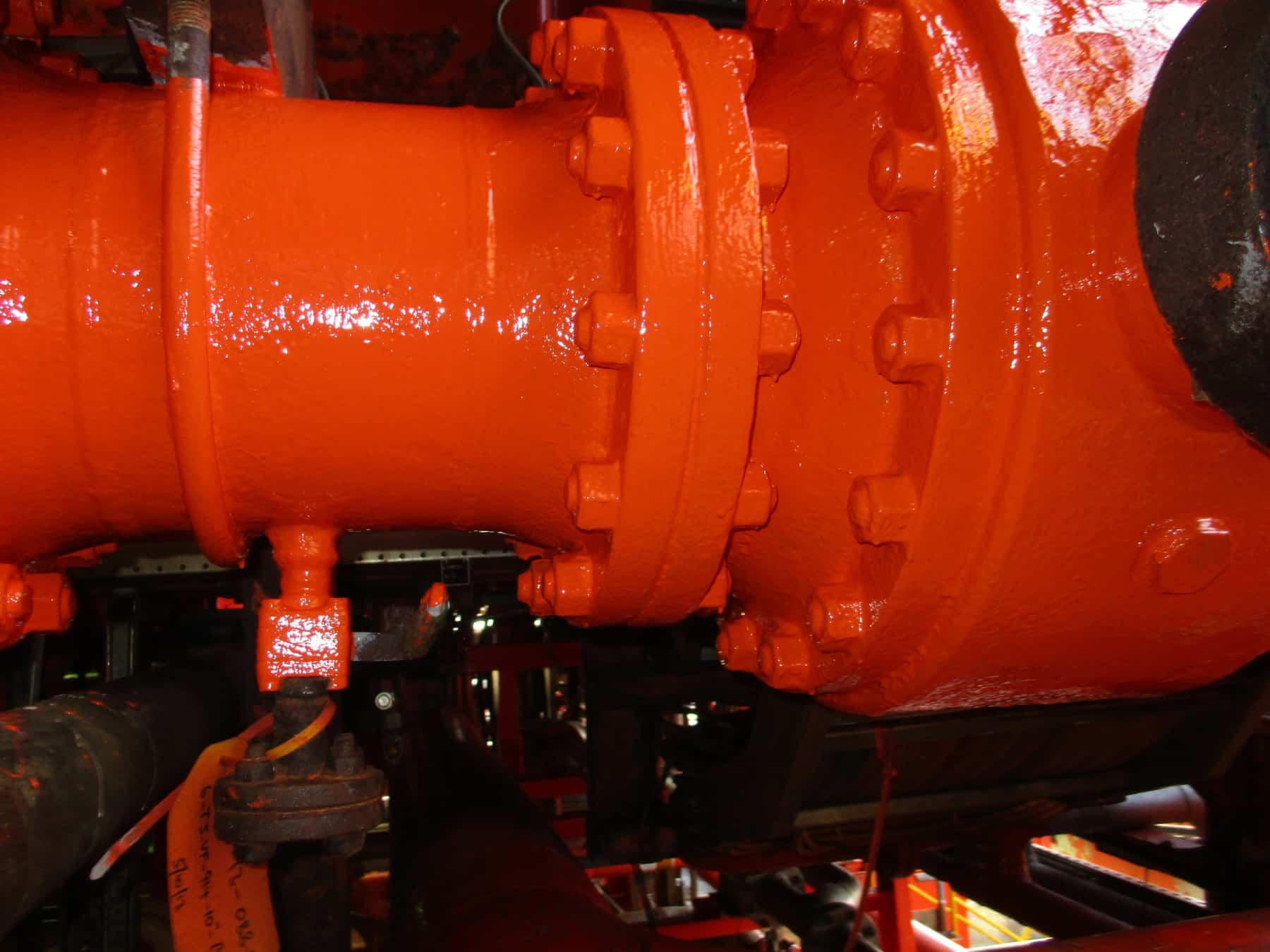

Vent to Flare Pipelines – Offshore Platform

OVERVIEW

The vent to flare pipelines on-board the offshore platform were suffering from corrosion damage and required to be refurbished.

CHALLENGE

Located 150 miles east of Aberdeen in the middle in the North Sea, coating application had to take place in extreme weather conditions.

There could be no disruption to the working platform and grit blasting was not permissible.

SOLUTION

The vent to flare pipelines were mechanically prepared.

Two primer coats of wet & rust tolerant RL 500PF were then applied.

This was followed by one topcoat of highly chemical and UV resistant RC 500GTC.

OUTCOME

The refurbishment process was carried out with no disruption to other ongoing work within the vicinity.

The coating contractor stated that utilising Chemco coatings had allowed other maintenance works to continue, and this would not have been possible utilising other paint systems.

Due to the success of this project, the same coating system has now been specified for further maintenance work required on the platform.

BENEFITS

• No grit blasting required

• No disruption to working platform

• Reduced cost of plant and equipment

• No humidity or dew point restrictions

• RL 500PF’s wet & rust tolerant properties ensured there was no weather constraints

• High chemical and UV resistance

• Substantial time and cost savings