CASE STUDY

Coal-tar Epoxy Patch Repair

OVERVIEW

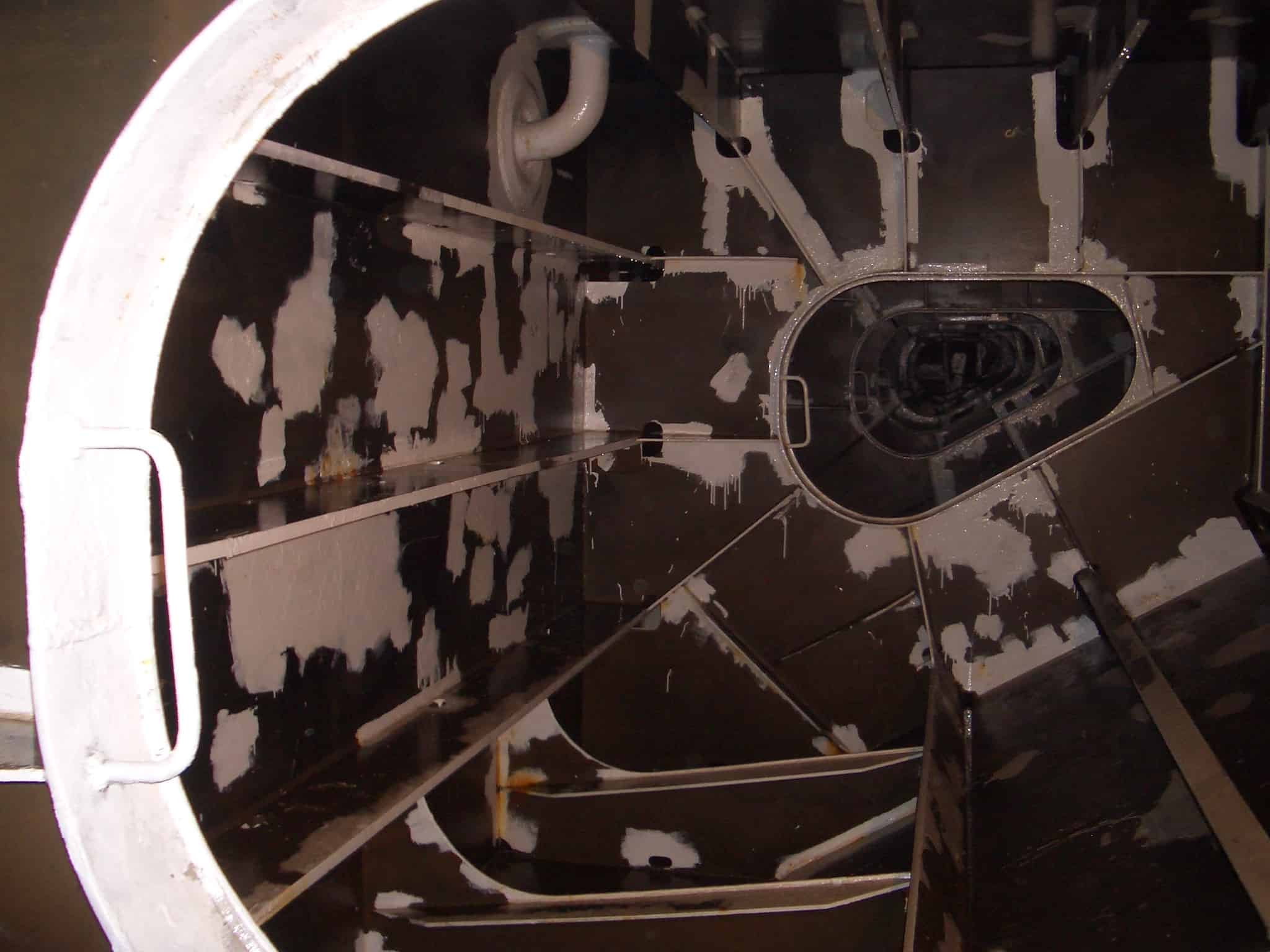

The ballast tanks on-board the Self Discharging Bulk Carrier had previously been coated with coal-tar epoxy. Areas within these ballast tanks were now showing signs of corrosion damage and required to be patch repaired.

CHALLENGE

To find a protective coating system which would be compatible with a coal-tar epoxy tank lining.

SOLUTION

Chemco’s Epo-chem™ RS 500P (primer) & RA 500M (topcoat) were selected as the protective coating system to be utilised as it is uniquely compatible with coal-tar epoxies. The areas which required the patch repair were mechanically prepared by power tooling to St2 standards. Upon completion of the surface preparation, one coat of solvent-free, wet & rust tolerant Epo-chem™ RS 500P was applied to the prepared areas. This was followed by one topcoat of solvent-free, wet tolerant Epo-chem™ RA 500M.

OUTCOME

The unique characteristics of Epo-chem™ RS 500P allowed the system to be applied with no compatibility issues and with strong adhesion to the coal-tar epoxy. The owners of this vessel are very satisfied with Chemco and issued a letter of recommendation. They also stated that after 5 years the coating is still in perfect condition.

BENEFITS

• Solvent-free

• No grit blasting

• Rust tolerant properties of Epo-chem™ RS 500P

• Compatibility with coal-tar epoxy

• Reduced H&S and Fire Precaution

• Substantial time and cost savings