CASE STUDY

New Build Ballast Tank Repair – Shop Primer

OVERVIEW

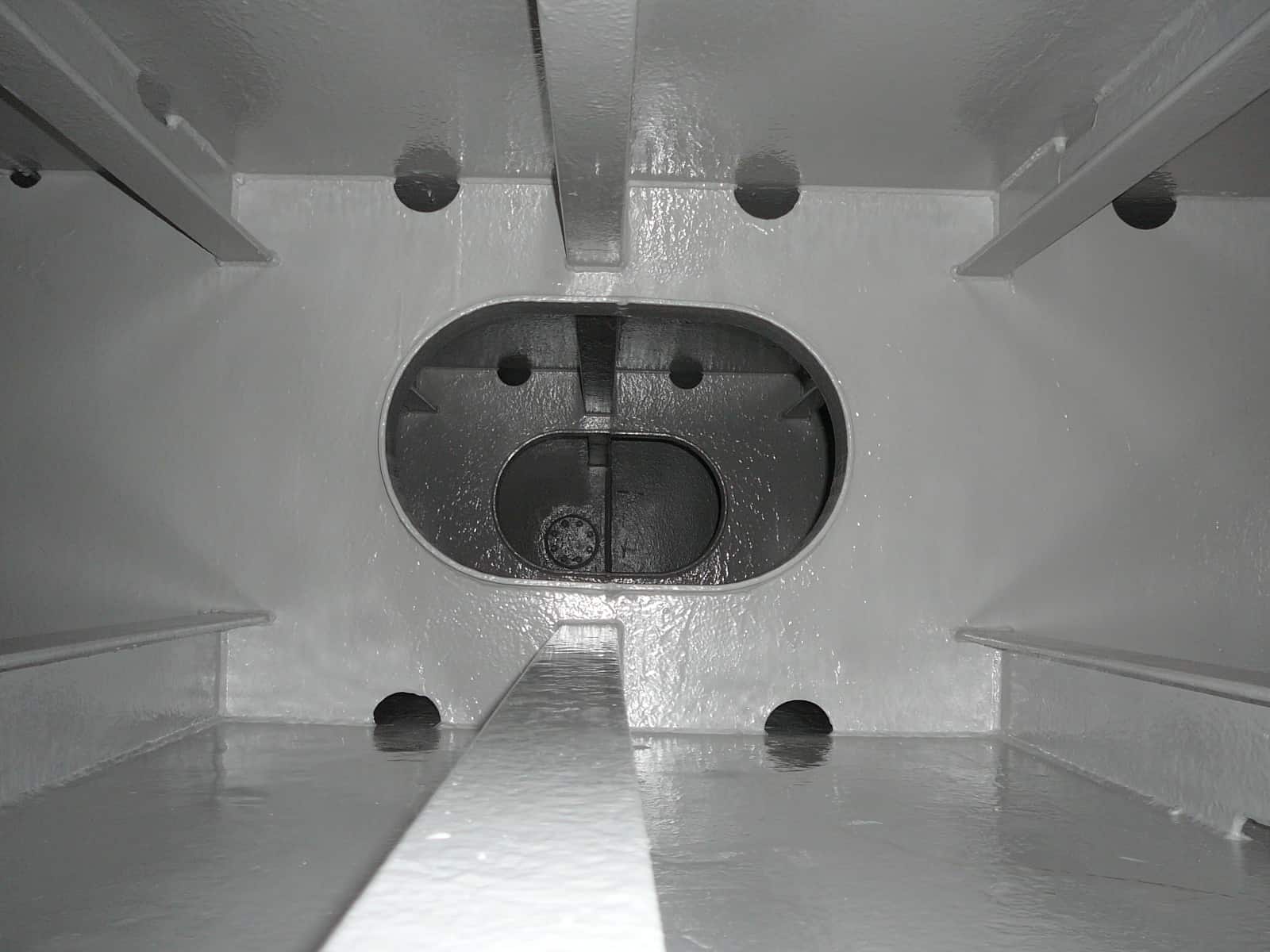

The Oil Products Tanker New Build required to have the double skin ballast tanks (over 5,000m²) coated with an IMO PSPC approved product.

The owners decided that they would select a solution which did not require grit blasting or solvent-based paints as the work had to be carried out in confined spaces. Traditionally, shop primers need to be completely removed prior to the application of a coating system.

The vessel was visited by its owners and Lloyds as this was the first New Build in the UK that was coated under the new IMO PSPC regulations.

CHALLENGE

The main challenge was to find a coating system which could be applied without the removal of the shop primer and without grit blasting.

Working in very tight, confined spaces also added to the difficulty of this project.

SOLUTION

Water jetting (500 bar) was utilised as the surface preparation method to remove any contaminants from the shop primed surfaces and the weld areas were mechanically prepared prior to the application of the IMO Approved Chemco System.

One stripe coat of solvent-free, wet & rust tolerant RS 500P was then applied, followed by one full coat, both at 100µm.

To complete the system, one topcoat of solvent-free, wet tolerant RA 500M was applied @ 250µm.

OUTCOME

The work was successfully completed and supervised by Baymarine’s QA and Chemco’s Technical Representative, meeting all the parameters for IMO and Lloyds Register for class certification.

BENEFITS

- Solvent-free

- Wet and rust tolerant

- No grit blasting requirement

- Reduced dehumidification and ventilation requirements

- Compatibility with shop primers (IMO approved)

- No recoating limitations

- Reduced H&S risk and threat of Fire Hazard

- Substantial time, cost and environmental savings