CASE STUDY

Splash Zone and Subsea Pipe Coating

– NORSOK M-501 System 7a

OVERVIEW

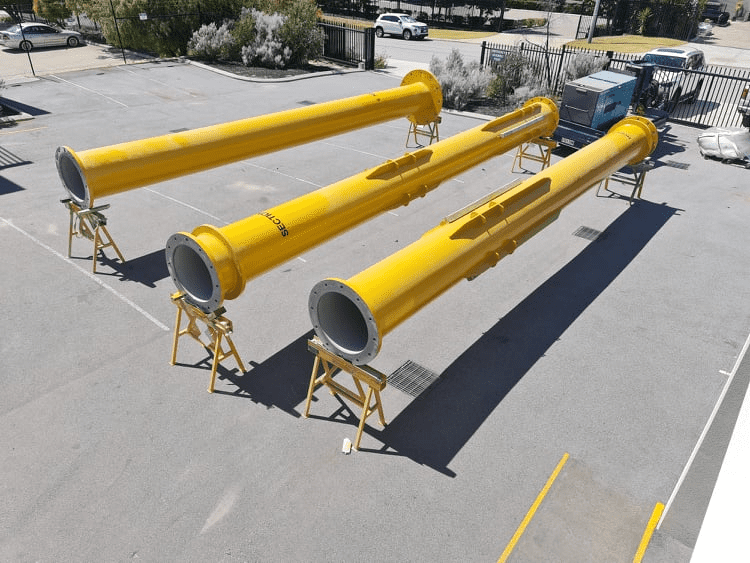

The J Pipes and Production Riser Pipes, to be used as part of a large offshore structure, required to be coated before being put into service.

The scope of work included coating the internals and externals of these pipes.

This project was carried out by Chemco’s representative in Western Australia, BCS Plus Holdings Pty Ltd.

CHALLENGE

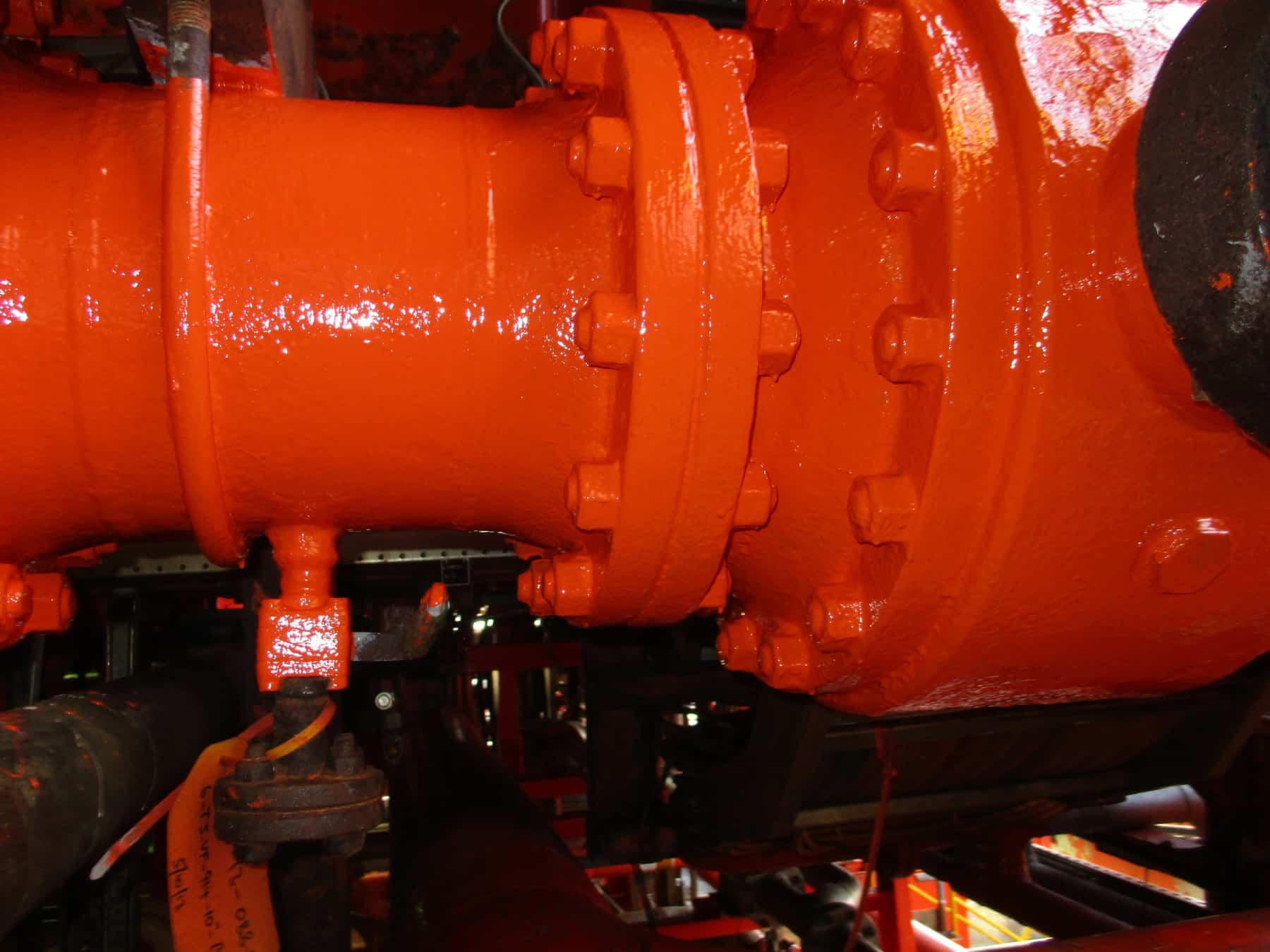

The pipes had to be coated in a system which could withstand the potentially highly corrosive conditions of an offshore environment, particularly in the splash zone areas.

Furthermore, much of the coated structure would be submerged underwater over a long period of time, whilst having to retain its colour, corrosion protection and chemical resistance properties.

SOLUTION

It was decided that a specification based on Chemco’s NORSOK M-501 System 7a was to be selected for the project, as follows:

| Pipe Internals | Pipe Externals (Splash Zone) | Pipe Externals (Subsea) |

|---|---|---|

| Primer Coat – RS 500P

Topcoat – RA 500M |

Primer Coat – RS 500P

Intermediate Coat – RA 500M Topcoat – RC 500GTC |

Primer Coat – RS 500P

Intermediate Coat – RA 500M Topcoat – RC 500GTC |

OUTCOME

The project was completed within the given timeframe, with all pipes set to be placed into service as part of the large offshore structure.

BENEFITS

- Solvent-free / VOC compliant

- Wet & rust tolerant

- Can be applied on minimally-prepared surfaces

- No humidity or dew point restrictions

- No recoating limitations

- Quick return-to-service

- Long term corrosion protection and chemical resistance

- Improved Health & Safety and reduced risk of Fire Hazard

- Excellent colour stability and opacity

- Amine, NCO and isocyanate-free